1. Battery production process testing: During the battery production process, the performance and status of the battery need to be comprehensively tested to ensure the quality and safety of the product. The battery probe can quickly and accurately test various parameters of the battery, providing important support for quality control in the production process.

2. Battery maintenance process detection: During the battery maintenance process, the status of the battery needs to be detected and evaluated to determine maintenance plans and replacement parts. The battery probe can quickly and accurately test various parameters of the battery, provide maintenance personnel with reliable maintenance solutions, and improve maintenance efficiency and accuracy.

3. Battery status monitoring: During battery use, the status of the battery needs to be monitored in real time to ensure the safety and reliability of the battery. The battery probe can quickly and accurately test various parameters of the battery, providing operators with real-time data so that problems can be discovered and dealt with in a timely manner.

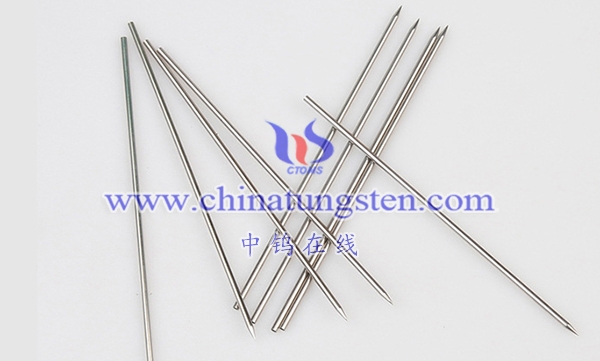

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595