The working principle of the tungsten wire ball probe is based on the resistance effect of the tungsten wire. Tungsten wire will exhibit high resistance characteristics at high temperatures, so when current passes through the tungsten wire, heat will be generated and the temperature of the tungsten wire will increase. If the external ambient temperature remains constant and there is no heat loss, the temperature of the tungsten wire will gradually increase and stabilize. However, when the tungsten wire is rapidly cooled, the electrons inside the tungsten wire will be strongly hindered due to its high resistance characteristics, causing the current to suddenly decrease. This phenomenon is called the “resistance effect.”

In electron microscopy testing, a tungsten ball probe is used as one of the electron sources. When an electric current passes through the tungsten wire, it is heated and produces a beam of high-energy electrons. When these electron beams scan the surface of the sample, they will stimulate various physical and chemical information of the sample. For example, electron beams can be used to excite the electronic transition of the sample, thereby obtaining information such as the energy band structure of the sample. At the same time, due to the high brightness and good stability of the tungsten filament ball probe, higher resolution and higher quality images can be obtained.

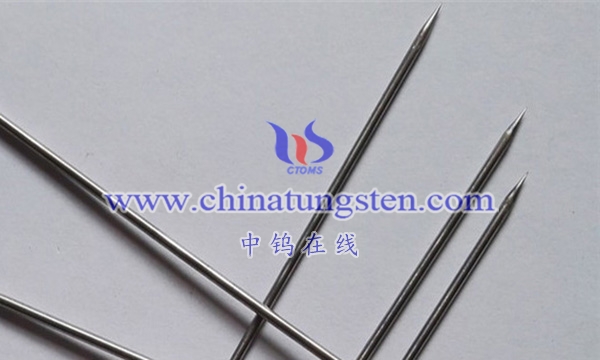

Tungsten ball probes have a relatively short service life and require frequent maintenance and replacement. In addition, due to the small size of the tungsten ball probe, installation and operation require certain skills and experience. Therefore, specialized knowledge and skills are required when using tungsten ball probes, and specialized equipment is required for testing and analysis.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595