The Soviet Union’s T-7 semi-superconducting device is a Tokamak-type nuclear fusion experimental device. It uses superconducting magnet technology, which allows it to more effectively confine high-temperature plasma under high magnetic fields, allowing for longer fusion reactions.

In the T-7 device, superconducting magnets are used to generate strong magnetic fields, which help control the shape and position of the plasma to prevent it from contacting the walls of the device and minimize energy loss. The application of this superconducting technology is an important milestone in fusion research because it significantly improves the efficiency and stability of magnetic confinement fusion.

The Soviet Union conducted a large number of experiments and research on the T-7 device and explored various conditions and parameters of the fusion reaction. These studies not only improved people’s understanding of fusion reactions, but also provided valuable experience and data for the design and operation of subsequent fusion experimental devices.

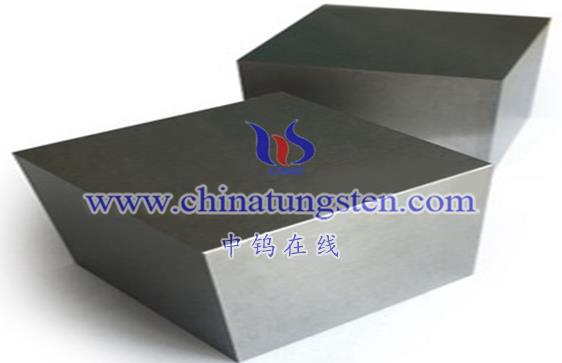

In the Soviet Union’s T-7 semi-superconducting device, the application of 90WMoNiFe alloy was mainly focused on the manufacturing of plasma-facing components. As an important tokamak device developed by the Soviet Union, T-7 also aims to explore and study the conditions and possibilities of nuclear fusion reactions.

First, 90WMoNiFe alloy was used to make the first wall in the T-7 due to its excellent high-temperature resistance. The first wall is the component in the tokamak device that directly faces the high-temperature plasma and needs to withstand extremely high thermal loads. 90WMoNiFe alloy can maintain structural stability and integrity in high-temperature environments, thereby ensuring long-term stable operation of the first wall in fusion reactions.

Secondly, 90WMoNiFe alloy is also used to make divertors. The divertor is a key component in the tokamak device, responsible for removing impurities and heat generated during the fusion reaction to maintain the purity and stability of the plasma. The anti-corrosion and anti-radiation properties of 90WMoNiFe alloy enable it to work for a long time in harsh environments, thereby extending the service life of the divertor.

In addition, 90WMoNiFe alloy may also be used in other structural components and support structures in the T-7 unit. These components also need to withstand the effects of high temperature, high pressure and radiation, and the excellent properties of 90WMoNiFe alloy enable these components to maintain structural stability and reliability under extreme conditions.

It is important to note that since the T-7 is a Soviet-era device, its design and manufacturing techniques may differ from modern devices. Therefore, the specific application of 90WMoNiFe alloy in T-7 may be limited by the technical level and material preparation process at that time. However, with the continuous advancement of science and technology and the in-depth development of fusion research, the application potential and advantages of 90WMoNiFe alloys in fusion devices have been gradually recognized and explored.

In short, 90WMoNiFe alloy is mainly used in the manufacturing of plasma-facing components in the Soviet T-7 semi-superconducting device, providing important material support for the exploration and research of fusion reactions.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595