The American TFTR (Tokamak Fusion Test Reactor) is a Tokamak fusion test reactor located at the Plasma Science and Fusion Center of the Massachusetts Institute of Technology in the United States. TFTR is the world’s first large-scale superconducting tokamak device and the main magnetic confinement fusion research device in the United States. Its goal is to verify the feasibility of the Tokamak fusion reactor and explore the commercial application prospects of fusion energy.

The main feature of TFTR is its superconducting magnet system, which allows it to operate at higher magnetic fields and longer pulse times, thereby improving plasma confinement performance. In addition, TFTR also uses a variety of advanced plasma heating and diagnostic technologies to achieve more precise control of fusion reactions.

During the operation of TFTR, scientists conducted a large number of fusion experiments, including high-energy plasma injection, neutral beam heating, and radio frequency wave heating. These experiments not only verified the basic principles of the tokamak fusion reactor, but also provided valuable data on fusion reaction kinetics, plasma transport and stability.

The successful operation and experimental results of TFTR provided important experience and support for subsequent international fusion cooperation projects such as the International Thermonuclear Experimental Reactor (ITER). It demonstrates the great potential of the Tokamak fusion reactor in the commercial application of fusion energy and provides an important research direction for mankind to find clean and sustainable energy solutions in the future.

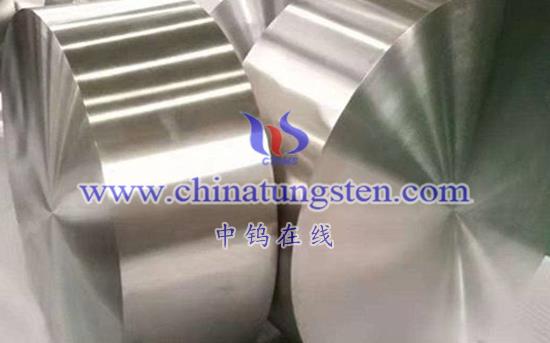

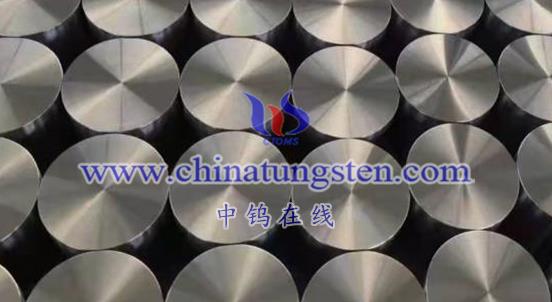

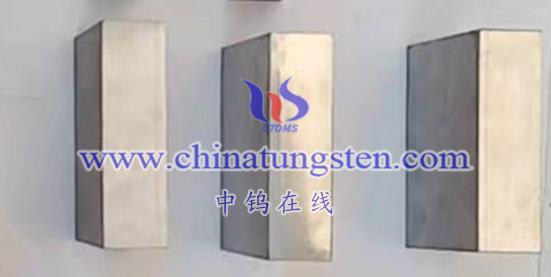

In the TFTR (Tokamak Fusion Test Reactor) in the United States, 90WMoNiFe alloy plays an important role and is mainly used in plasma-facing components and some structural supports.

First of all, as an important fusion research device, TFTR’s core goal is to realize and study high-temperature plasma behavior, and then explore the possibility of nuclear fusion reactions. In such an experimental environment, components facing the plasma, such as the first wall and divertor, are directly exposed to the bombardment of high-energy plasma and therefore need to withstand extremely high thermal loads and particle impacts. 90WMoNiFe alloy is an ideal material for the manufacture of these parts due to its excellent high temperature resistance and corrosion resistance. It can operate stably for a long time, maintain structural integrity and performance stability, and provide reliable guarantee for TFTR experimental research.

Secondly, 90WMoNiFe alloy is also used to make some structural supports in TFTR. These supports need to withstand the weight of the device and the forces generated during operation, while maintaining stability in high temperature and radiation environments. The high strength and good mechanical properties of 90WMoNiFe alloy enable it to meet these requirements and ensure the structural safety and stable operation of TFTR.

In addition, with the deepening of fusion research and the continuous advancement of technology, the requirements for material performance are also constantly increasing. In response to the specific needs of TFTR devices, researchers may also optimize and improve the 90WMoNiFe alloy to improve its performance and reliability in extreme environments.

To sum up, 90WMoNiFe alloy plays a key role in the American TFTR. Its excellent high temperature resistance, corrosion resistance and mechanical properties provide strong support for the stable operation of the device and fusion research.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595