The WEST (West European Torus) device is an all-tungsten divertor superconducting tokamak device that is being upgraded by the French Atomic Energy Commission. It is mainly used to carry out prototype component testing to promote the construction of the International Thermonuclear Experimental Reactor (ITER). The device, which was renamed WEST in 2016 after extensive upgrades that began in 2013, produced its first plasma on December 14 of the same year.

During the construction and operation of the WEST device, the Institute of Plasma Physics, Hefei Institute of Physical Sciences, Chinese Academy of Sciences, played an important role. They successfully developed the key component divertor for the WEST unit, which was officially completed and delivered in 2020 and will be shipped to France for installation. The divertor is the core component of the WEST device and plays a key role in achieving long-pulse, high-parameter operation and its main scientific goals. At the same time, they also undertook the development task of the first set of ion gyro antennas for the WEST device. This was also the first time that my country exported fusion engineering technology to France and provided key components for the WEST device.

The ITER project is one of the most important international scientific and technological cooperation programs in the world. It aims to build a superconducting Tokmak device capable of producing large-scale nuclear fusion reactions. The successful construction and operation of the WEST device will not only help promote the development of the ITER project, but also provide important scientific and technical support for mankind to realize the commercial application of nuclear fusion energy at an early date.

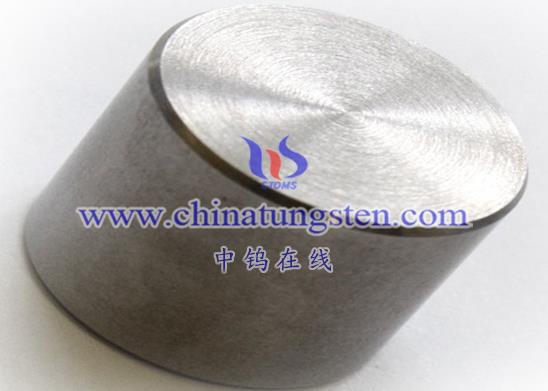

In Frances WEST (Wendelstein 7-X Enhanced Stellarator) device, the application of 90WMoNiFe alloy is mainly focused on plasma-facing components and structural supports.

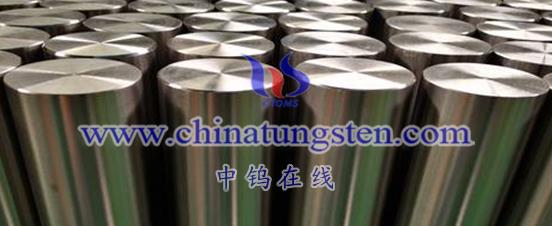

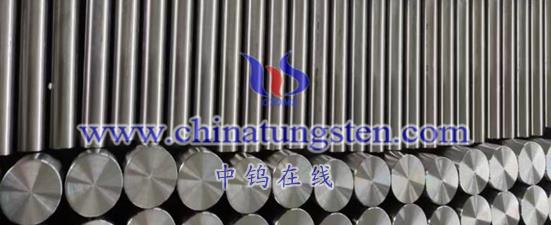

First, plasma-facing components are key components in fusion reaction devices, and they are directly exposed to extreme high temperatures and high-energy particle environments. In the WEST device, 90WMoNiFe alloy was selected as the material for components such as the first wall and divertor due to its excellent high temperature resistance, corrosion resistance and radiation resistance. These components need to withstand the thermal load and particle impact from the plasma, and 90WMoNiFe alloy can maintain the stability and integrity of the structure and ensure the stable progress of the fusion reaction.

Secondly, structural supports play the role of supporting and fixing various components in the fusion device to ensure the stable operation of the entire device. In the WEST installation, 90WMoNiFe alloy is also used to manufacture some key structural supports. These supports need to have high strength and good mechanical properties to withstand the various forces and stresses during device operation. The excellent properties of 90WMoNiFe alloy make it an ideal choice for manufacturing these supports.

In addition, as an advanced fusion research platform, the WEST device has also conducted a series of experimental studies on material properties and plasma behavior. In this process, 90WMoNiFe alloy, as a material for components facing the plasma, provides researchers with valuable experimental data and experience, which helps to further optimize the design and operating parameters of the fusion device.

In general, the application of 90WMoNiFe alloy in the French WEST device is mainly reflected in plasma-facing components and structural supports. Its excellent performance provides a strong guarantee for the stable progress of the fusion reaction and the safe operation of the device.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595