The technical difficulties of the all-tungsten divertor superconducting tokamak device are mainly reflected in the following aspects:

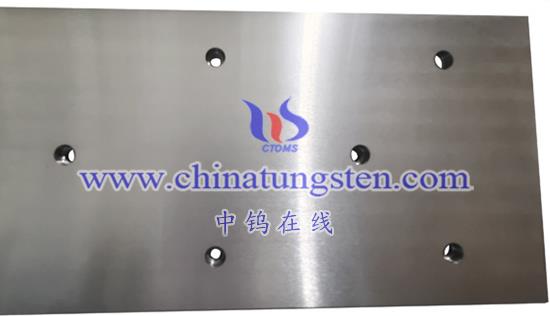

Mass production of high-performance rolled tungsten materials

In order to meet the long-term and high-load operation requirements of the device, a large amount of high-performance rolled tungsten materials need to be produced. This involves issues such as optimization of material preparation processes, improvement of production efficiency, and stable control of product quality.

Multilayer hot isostatic pressing composite technology

The composite between tungsten, copper, chromium, zirconium and copper requires hot isostatic pressing technology. The technical difficulty lies in how to ensure a good interface bond between different materials while maintaining stable overall performance of the composite material.

Non-destructive testing technology

Since the working environment of the divertor is extremely harsh, its quality requirements are also very high. Therefore, the application of non-destructive testing technology is crucial. This involves how to accurately and efficiently detect defects and damage in composite materials to ensure the safe operation of the device.

Precise control during welding and forming processes

During the welding and forming process of tungsten-copper strings, it is necessary to strictly control the gap size between the tungsten blocks and the quality of the welding interface. This requires extremely high precision and stability in the welding process to ensure that the welded joints have good mechanical properties and corrosion resistance.

In summary, the research and development of the all-tungsten divertor superconducting tokamak device involves multiple technical difficulties, which requires scientific researchers to continue to explore and innovate to promote the in-depth development of nuclear fusion research. Overcoming these technical difficulties will not only help improve the performance and stability of the device, but also lay a solid foundation for achieving clean and sustainable energy supply in the future.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595