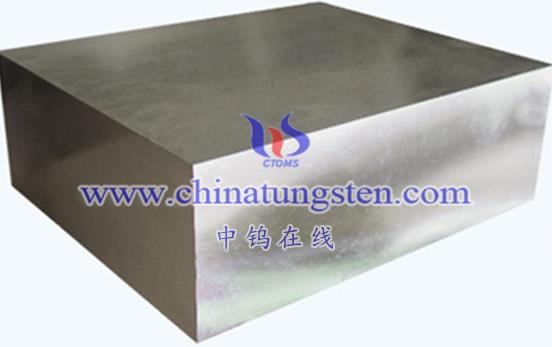

90WMoNiFe alloy is mainly used in a series of key components and supports in the TFTR (Tokamak Fusion Test Reactor) in the United States. These components and supports play a vital role in the fusion reaction.

First, 90WMoNiFe alloys are widely used in the fabrication of plasma-facing components, such as first walls and divertors. The first wall is the component that directly faces the high-temperature plasma in the fusion reaction and needs to withstand extremely high thermal load and particle flow impact. The divertor is used to remove impurities and heat generated during the reaction and keep the plasma pure and stable. 90WMoNiFe alloy is an ideal material for manufacturing these critical components due to its excellent high temperature resistance, corrosion resistance and radiation resistance.

Secondly, 90WMoNiFe alloy is also used to make structural supports in TFTR. These supports need to withstand the weight of the device and the forces generated during operation, while maintaining stability in high temperature and radiation environments. The high strength, good mechanical properties and excellent thermal stability of 90WMoNiFe alloy enable it to meet these harsh working conditions and ensure the structural safety and stable operation of TFTR.

In addition, 90WMoNiFe alloy may also be used in other key components in TFTR, such as diagnostic windows, heat shields, etc. These components also need to withstand the effects of high temperature, high pressure and radiation, and the excellent properties of 90WMoNiFe alloy can ensure their reliability and safety under extreme conditions.

In summary, the application of 90WMoNiFe alloy in TFTR covers many key areas such as plasma-facing components and structural supports, providing an important guarantee for the stable progress of the fusion reaction and the safe operation of the TFTR device.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595