Thorium based molten salt reactor

Thorium Molten Salt Reactor (TMSR) is a new type of nuclear energy reactor that uses thorium-based molten salt as fuel liquid to perform nuclear reactions at high temperatures. The reactor uses molten salt fuel and thorium-232 as breeder fuel, utilizing the thorium-uranium cycle production capacity. The specific method is to convert thorium-232 into another nuclear fuel, uranium-233, in a thermal neutron reactor, and then separate the uranium-233 and return it to the reactor for recycling.

The basic principle of the thorium-based molten salt reactor is to generate a large amount of thermal energy by controlling the reaction of thorium ions in the molten salt with neutrons. This thermal energy can be converted into electrical energy through a heat exchanger. It has high safety because the heat energy generated by the reaction of thorium ions and neutrons decreases as the temperature increases, and will not cause excess heat energy to cause an explosion. In addition, the thorium-based molten salt reactor has a very high combustion efficiency and produces very little nuclear waste, so it is called a nuclear waste-free nuclear reactor.

The thorium-based molten salt reactor is considered one of the safest reactor technologies in the future among the six reactor types in the International Forum on Generation IV Nuclear Energy Systems. It can not only be used for power generation, but also for high-temperature hydrogen production and molten salt energy storage, helping to create a multi-energy integrated clean energy system.

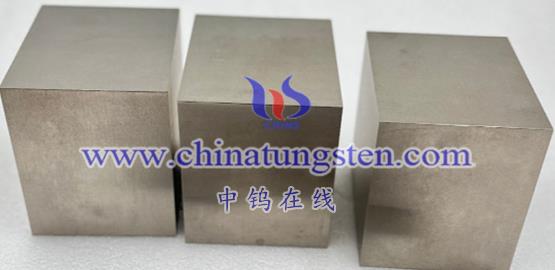

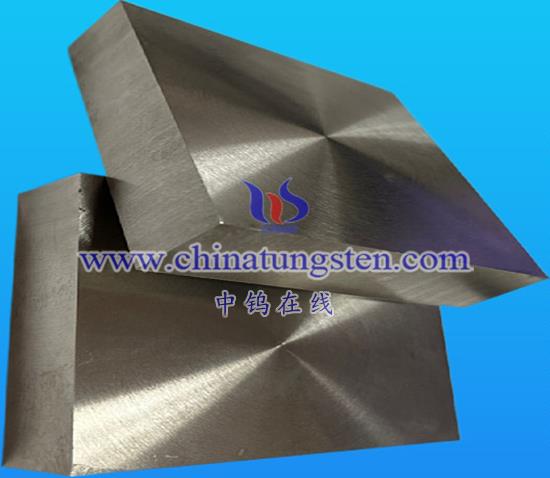

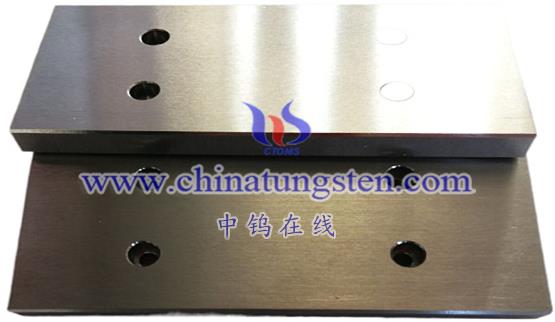

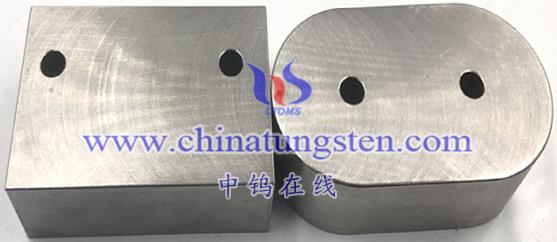

The application of 90WMoNiFe alloy in thorium-based molten salt reactors is mainly reflected in its role as a key material component. Since thorium-based molten salt reactors operate in high temperature and strong radiation environments, which require extremely high material performance, 90WMoNiFe alloy has become an ideal candidate material due to its excellent high temperature resistance, radiation resistance and corrosion resistance.

Specifically, the application of 90WMoNiFe alloy in thorium-based molten salt reactors may include the following aspects:

Reactor internal structural materials

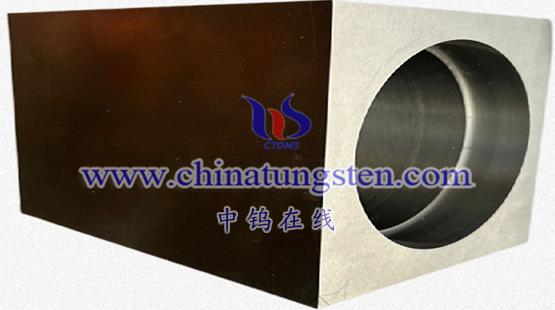

Because thorium-based molten salt reactors need to operate at high temperatures, their internal structural materials need to be able to withstand extremely high temperatures. The high melting point and excellent thermal stability of 90WMoNiFe alloy make it an ideal material for manufacturing reactor internal structures, such as reactor vessels, heat exchangers, pipes, etc.

Fuel Containers and Pipes

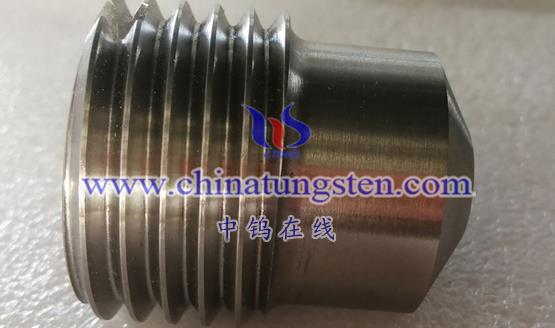

In a thorium-based molten salt reactor, the molten salt fuel needs to be safely stored and transported. 90WMoNiFe alloy is resistant to corrosion from molten salts, and its high strength and high temperature resistance make it suitable for use in the manufacture of fuel containers and delivery pipes.

radiation shielding materials

Because thorium-based molten salt reactors produce radiation during operation, radiation shielding materials are required to protect personnel and equipment around the reactor. The radiation resistance of 90WMoNiFe alloy makes it an effective radiation shielding material that can reduce the risk of radiation leakage.

Control rods and structural supports

In a reactor, control rods are used to regulate the speed of nuclear reactions, while structural supports are used to maintain stable operation of the reactor. 90WMoNiFe alloy is suitable for manufacturing these critical components due to its good mechanical properties and high temperature resistance.

Although 90WMoNiFe alloy has potential application value in thorium-based molten salt reactors, practical applications also need to consider the material’s processing performance, cost, and compatibility with other materials. In addition, with the continuous development of thorium-based molten salt reactor technology, the requirements for material properties may also change, so the properties of 90WMoNiFe alloys need to be continuously optimized and improved.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595