90WMoNiFe alloy has various applications in the field of machinery manufacturing, which mainly benefit from its excellent physical and chemical properties. Here are some of the main application areas:

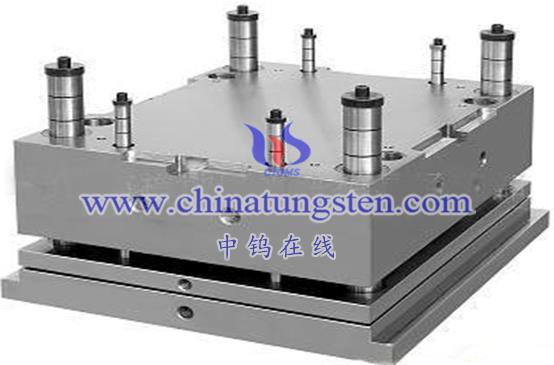

Die casting mold

90WMoNiFe alloy is widely used in the manufacture of die-casting molds due to its low expansion coefficient, high thermal conductivity and good red hardness. These properties allow the alloy to maintain dimensional stability during the die-casting process, improving the service life of the mold and product quality.

Tool racks and boring bars

In the machinery manufacturing process, tool holders and boring bars are critical components. 90WMoNiFe alloy is often used to manufacture these parts due to its high strength, wear resistance and corrosion resistance to improve its service life and machining accuracy.

automatic watch hammer

90WMoNiFe alloy is also used to make automatic watch hammers. The high hardness and good wear resistance of this alloy enable the watch hammer to maintain stable performance under high-speed operation, improving the accuracy and reliability of the watch.

Counterweights and counterweights

In machinery manufacturing, counterweights and counterweights are commonly used components. 90WMoNiFe alloy is often used to manufacture these components due to its high density and good mechanical properties to achieve balanced and stable operation of equipment.

In summary, 90WMoNiFe alloy has a wide range of applications in the field of machinery manufacturing and can meet various complex and harsh working environment requirements. With the continuous advancement and development of mechanical manufacturing technology, the application prospects of 90WMoNiFe alloy in this field will be broader.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595