Tungsten-molybdenum-nickel-iron alloy hot runner system is a hot runner technology used in injection molds. This system uses tungsten-molybdenum-nickel-iron alloy as the heating element and flow channel material to provide uniform and stable heating effects and optimize the flow properties of the plastic.

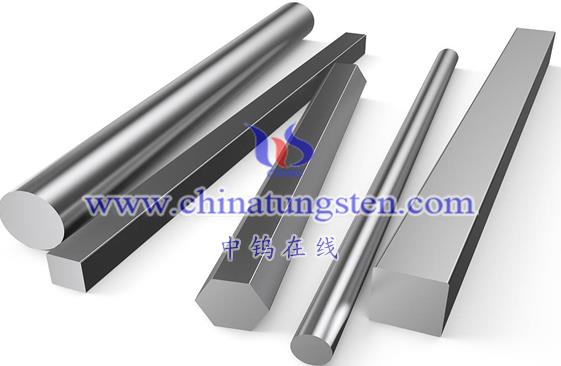

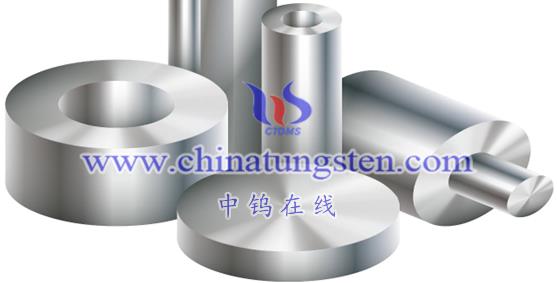

Tungsten-molybdenum-nickel-iron alloy is a high-performance alloy with high temperature stability, high thermal conductivity, high corrosion resistance and high mechanical strength. These properties make the alloy have excellent performance in hot runner systems and can meet the high requirements for heating elements and runner materials during the injection molding process.

In the tungsten-molybdenum-nickel-iron alloy hot runner system, the heating element is placed in the flow channel of the mold, and stable heat is provided through electric heating to keep the plastic in a molten state in the flow channel, thereby achieving continuous and uniform plastic flow. The system is also equipped with a temperature control device that can accurately control the temperature of the heating element to meet the injection molding requirements of different plastics.

In addition, the tungsten-molybdenum-nickel-iron alloy runner material has good high temperature resistance and corrosion resistance, and can withstand the high temperature and corrosive environment during the injection molding process, ensuring the stability and service life of the runner.

In short, the tungsten-molybdenum-nickel-iron alloy hot runner system is an efficient, stable and reliable injection mold hot runner technology, suitable for the production of various plastic products that require high precision and high quality.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595