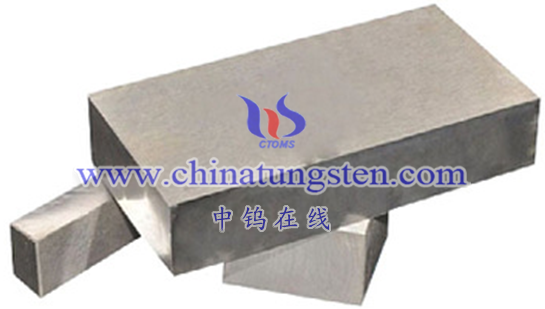

90WMoNiFe high-entropy alloy has many significant advantages, which make it widely used in many fields. Here are some of the main advantages:

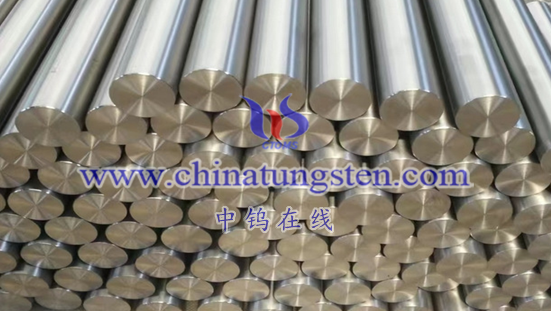

High strength and hardness

Tungsten-molybdenum-iron high-entropy alloy has excellent strength and hardness, which allows it to withstand high loads and resist wear. Therefore, it has wide applications in manufacturing heavy-duty equipment, cutting tools and wear-resistant parts.

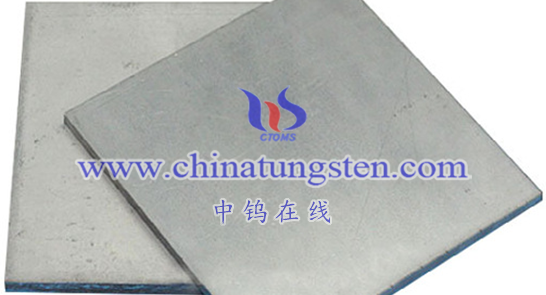

good corrosion resistance

The alloy has good corrosion resistance to a variety of chemical media, including acids, alkalis and salts. This enables it to operate stably for a long time in chemical, petroleum, marine engineering and other environments.

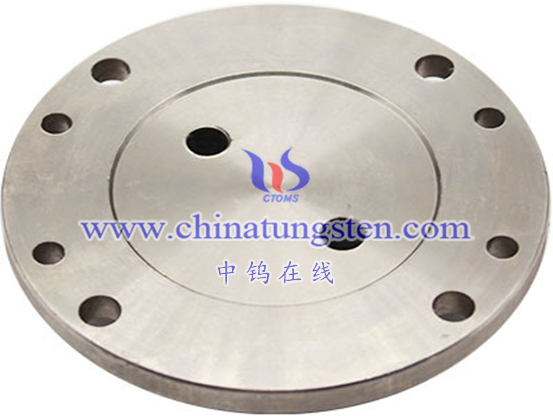

High temperature stability

90WMoNiFe high-entropy alloy can maintain stable performance in high-temperature environments and is not prone to deformation or failure. This makes it important for manufacturing high-temperature components in areas such as aerospace, energy and automotive manufacturing.

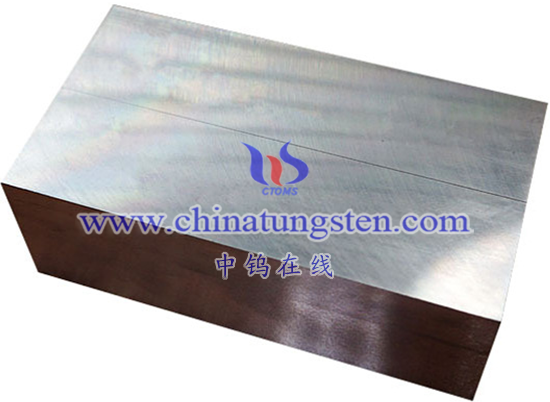

Excellent mechanical properties

The alloy has high strength, high toughness and excellent tensile resistance. These mechanical properties make it ideal for manufacturing highly loaded components and structural materials.

Unique composition and properties

As a type of high-entropy alloy, 90WMoNiFe high-entropy alloy consists of various elements, and the content of each element is within a certain range. This unique composition makes it possible to have some special properties and application potential that traditional alloys do not have.

Although 90WMoNiFe high-entropy alloys have many advantages, factors such as cost, processing performance, and compatibility with other materials need to be considered in practical applications. Therefore, further research and exploration are needed in specific applications.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595