The production process of porous tungsten mainly relies on powder metallurgy methods, which involve multiple key steps. Here is a rough description of the production process:

Firstly, select appropriate tungsten powder as the raw material, which can be regular tungsten powder or spherical tungsten powder. The selection of raw materials has a significant impact on the performance of the final product. Next, pre-treatment of tungsten powder, such as oxidation treatment, is carried out to change its surface properties or generate the required mixed powder.

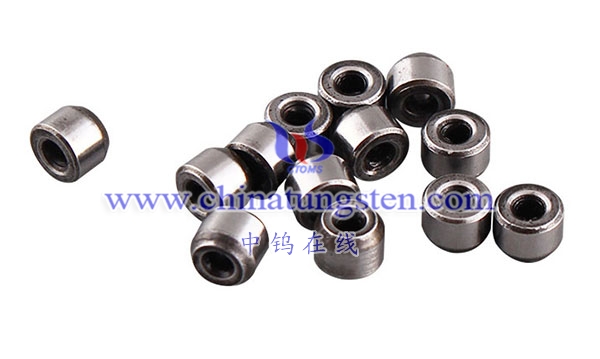

Then, the processed tungsten powder is pressed into shape to obtain the desired shape and density of the tungsten billet. During the pressing process, it is necessary to control the pressure to ensure that the structure of the billet is uniform and dense.

Subsequently, the pressed tungsten billet is sintered. Sintering is a crucial step in the powder metallurgy process, which involves high-temperature treatment to induce metallurgical bonding between powder particles, resulting in porous tungsten products with certain strength and pore structure. The sintering temperature and atmosphere are important factors affecting the performance of porous tungsten, and precise control is required according to specific requirements.

During the sintering process, the pores between the powder particles will be retained, forming a porous structure. By controlling the sintering process and the properties of the raw material powder, precise control of the porosity and pore size of porous tungsten can be achieved.

Finally, the sintered porous tungsten products are subjected to subsequent treatments such as polishing, cleaning, etc. to obtain the final product.

The description is only a rough description of the production process, and the specific production process may vary due to factors such as raw materials, equipment, and process parameters. Meanwhile, in order to achieve better performance or meet specific requirements, more complex process treatments or the introduction of other auxiliary materials may also be necessary.

Overall, the production process of porous tungsten is a complex and delicate process that requires comprehensive consideration of multiple factors to obtain the desired product.

More details of tungsten barium elecrode or tungsten barium cathode, please visit website: http://tungsten.com.cn/barium-tungsten-cathode.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595