According to the following process, the barium tungsten cathode can generally be fully activated. However, due to the different heating equipment, temperature measurement methods, and vacuum systems of each company’s equipment, the following conditions are for reference only. It is best to calibrate the temperature measurement system before activation, and after multiple tests, determine the optimal activation temperature and time to improve the vacuum degree of the lamp making process as much as possible.

Temperature, time, and vacuum degree need to be adjusted according to the size of the electrode or lamp tube. Large lamps or electrodes require higher temperature, longer time, and higher vacuum degree.

The activation of electrodes and the maintenance of low vacuum during the lamp installation process can improve the performance and stable quality of the lamp.

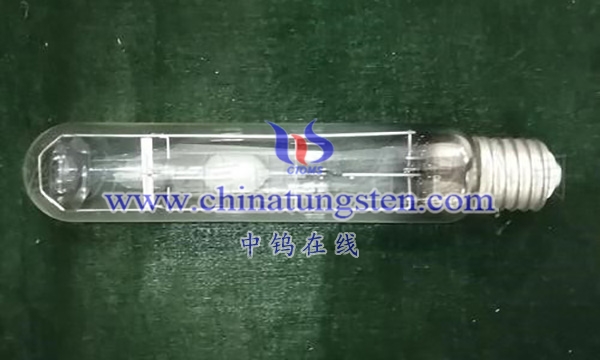

The activation process can be divided into two steps. The first step is to remove impurities and oxides from the electrode; The second step is the activation of salt, which needs to be completed through diffusion in high temperature, long time, and high vacuum environments. Both steps are very important. When there is residual water vapor in the lamp tube, the tungsten base will react with H2O to generate WO3, which will deposit in the form of black dots on the inner wall of the glass. Inadequate activation will affect the lifespan of the lamp tube.

1) Heat the lamp tube and electrode to 700-850 ℃, and continue heating and vacuuming. This process is to remove impurities such as water from the electrode and lamp tube. When the vacuum level no longer decreases and is below 10-5Pa, start the activation of the second step;

2) Slowly raise the temperature to 1200 ℃ and maintain it for 1-2 hours. During this process, the vacuum degree should only slightly increase. If the vacuum degree increases significantly, it may be due to the large evaporation of barium salts. It is necessary to lower the temperature appropriately. When the activation step is about to be completed, the pressure inside the lamp tube should be between 10-6-10-7Pa, so that the cathode is fully activated.

3) The electrodes can be activated one by one during the lamp installation process, or multiple electrodes can be systematically placed in quartz tubes for unified activation before use. After activation is completed, argon gas is injected into the quartz tube, and after a short period of storage, it can be turned on and used immediately.

More details of tungsten barium elecrode or tungsten barium cathode, please visit website: http://tungsten.com.cn/barium-tungsten-cathode.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595