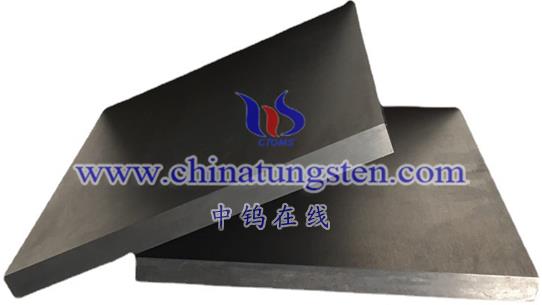

90 WMoNiFe Alloy Cooling Insert is a special alloy material used in cooling systems in mold manufacturing. It combines the advantages of metal elements such as tungsten, molybdenum, nickel and iron to form an alloy material with high performance, high thermal stability and good processing performance. The alloy is used to manufacture cooling inserts to improve the cooling efficiency and service life of the mold.

Professional term explanation

High-Entropy Alloys (HEAs): A new type of alloy composed of multiple elements with approximately equal content of each element, which achieves excellent performance through alloy design.

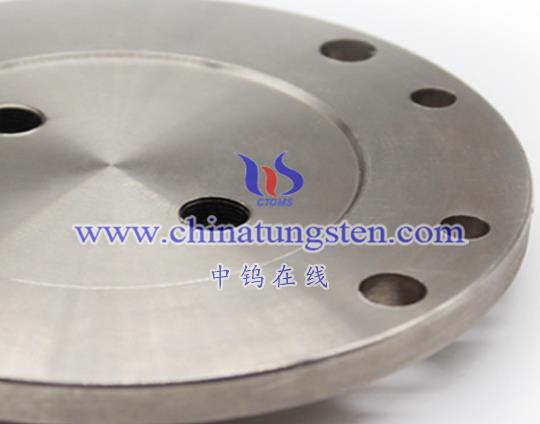

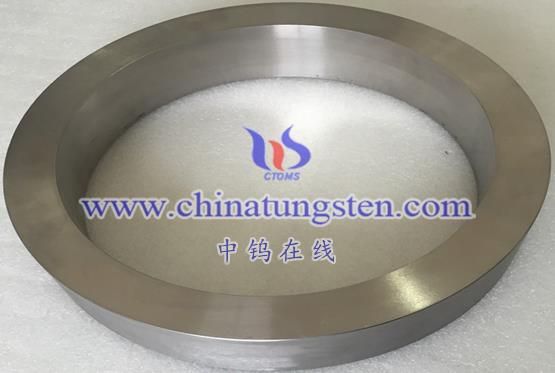

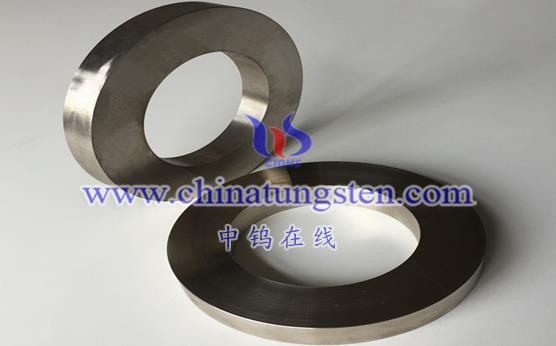

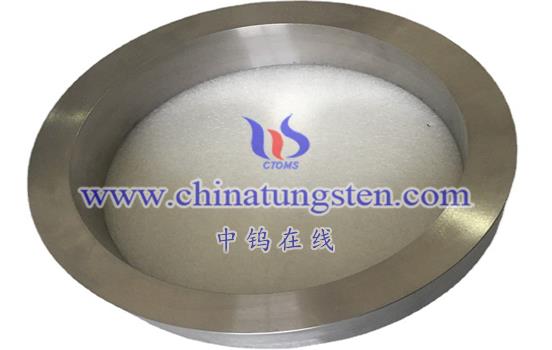

Cooling Insert: A cooling component embedded in the mold, used to introduce coolant into the mold to achieve rapid and uniform cooling.

Thermal Stability: The ability of a material to maintain its physical and chemical properties stable in a high temperature environment.

Wear Resistance: The ability of a material to resist wear, usually quantified by wear rate.

Hot Hardness: The ability of a material to maintain hardness at high temperatures is an important indicator for evaluating the performance of mold materials.

Main features

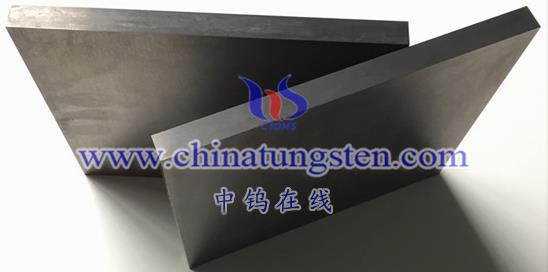

High temperature performance: 90 WMoNiFe alloy can maintain stable hardness and strength at high temperatures and is suitable for high temperature working environments.

Excellent thermal conductivity: The alloy has good thermal conductivity, can effectively transfer heat and improve cooling efficiency.

High wear resistance: The high hardness and wear resistance of the alloy give the cooling insert a long service life.

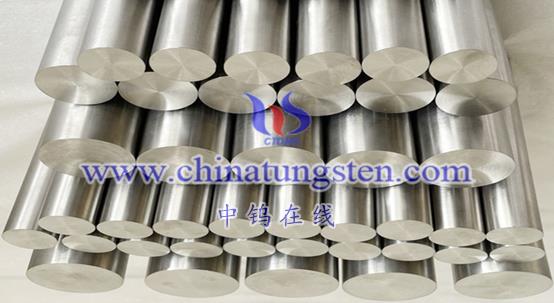

Good processability: Although the hardness is high, the alloy can still be processed into complex shapes and structures through proper process control.

Application areas

90 WMoNiFe alloy cooling inserts are widely used in working environments that require high temperature and high strength, such as die casting molds, hot forging molds and heat treatment equipment.

Related data

Chemical composition: Generally, the chemical composition range of 90 WMoNiFe alloy is roughly: W 20-30%, Mo 20-30%, Ni 20-30%, Fe balance. The specific composition is adjusted according to the design and purpose of the alloy.

Physical properties: Physical properties data such as density, thermal expansion coefficient, thermal conductivity, etc. are crucial to the understanding and application of 90 WMoNiFe alloy cooling inserts.

Mechanical properties: including tensile strength, yield strength, elongation, impact toughness, etc. These performance indicators determine the performance of the alloy in engineering applications.

Corrosion resistance: Corrosion resistance data in specific environments (such as acid and alkali solutions, high-temperature oxidizing atmospheres, etc.) is crucial for evaluating the service life of the alloy.

90 WMoNiFe alloy cooling inserts have broad application prospects in the mold industry due to their high-temperature stability, excellent thermal conductivity and wear resistance. With the continuous development of new materials and processing technologies, the performance and application areas of this alloy will be further expanded.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595