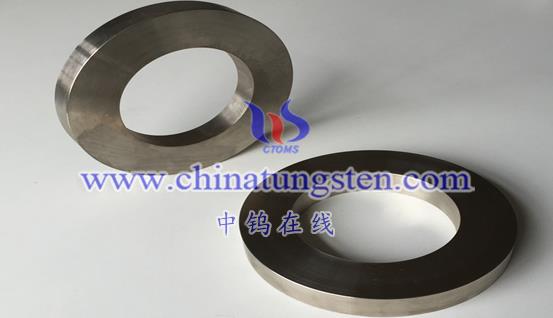

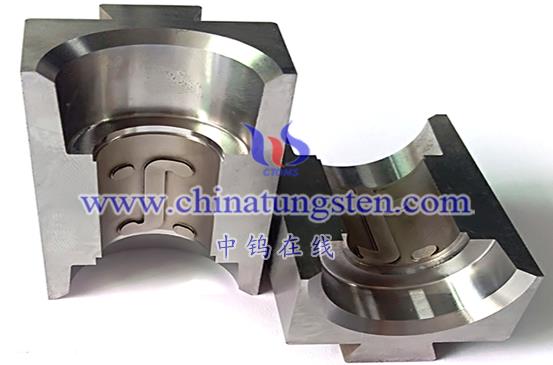

90 WMoNiFe alloy cooling inserts have a series of significant features and advantages, making them widely used in mold manufacturing and related fields. The following are the main features and benefits of this alloy cooling insert:

Excellent high temperature performance

90 WMoNiFe alloy maintains excellent stability and strength in high-temperature environments. This alloy has high thermal stability and thermal fatigue resistance, and can maintain the stability of its structure and performance even under long-term high-temperature operating conditions. This makes it ideal for manufacturing high-temperature molds and cooling inserts that need to withstand high-temperature shocks.

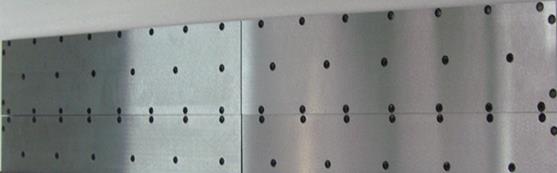

Excellent thermal conductivity

90 WMoNiFe alloy has excellent thermal conductivity and can effectively conduct heat quickly from the inside of the mold to the cooling medium. This efficient heat conduction capability helps achieve rapid and uniform cooling, thereby improving mold production efficiency and product quality.

Good wear and corrosion resistance

The alloy has excellent wear and corrosion resistance, allowing it to maintain long-term stability in harsh working environments. It is less susceptible to chemical corrosion and wear, extending the life of the cooling insert and reducing the frequency of maintenance and replacement.

High hardness and strength

90 WMoNiFe alloy has high hardness and strength, allowing it to withstand high pressure and heavy-load working conditions. This high hardness allows the cooling insert to better resist deformation and wear in the mold, maintaining the accuracy and stability of the mold.

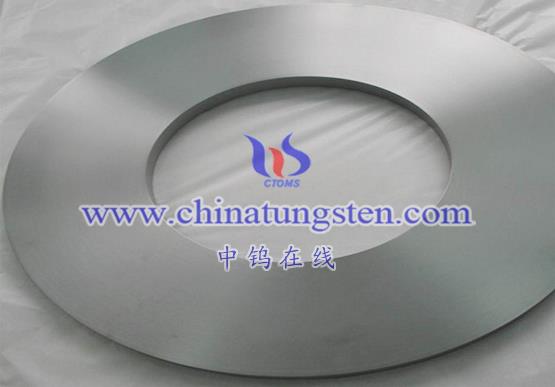

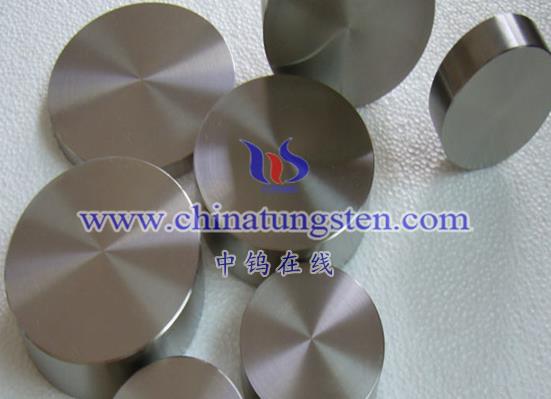

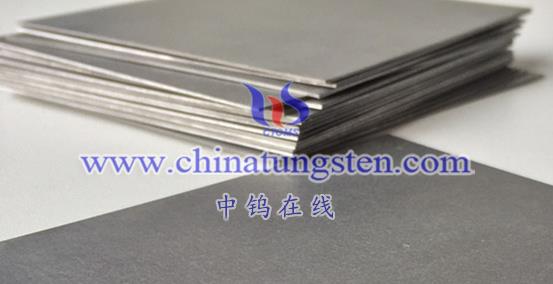

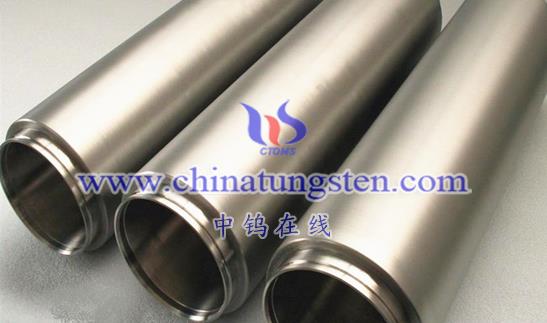

Good processability and plasticity

Although 90 WMoNiFe alloy has high hardness, through proper process control and processing technology, it can be processed into various shapes and sizes to meet the needs of different molds. This good processability and plasticity allows the alloy greater flexibility in mold design and manufacturing.

90 WMoNiFe alloy cooling inserts have become an indispensable and important component in the field of mold manufacturing due to their excellent high-temperature performance, thermal conductivity, wear resistance, corrosion resistance, hardness and strength. It can improve the production efficiency, product quality and service life of molds, and provide strong support for the development of the manufacturing industry.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595