In the field of metal processing and molding, especially in mold manufacturing, the sprue bushing is a vital component. The sprue bushing, also known as the sprue bushing or feed bushing, is the part of the mold used to guide the molten material into the cavity. Because it is subjected to the impact of high temperature, high pressure and high-speed flowing molten materials, its material is required to have excellent wear resistance, high temperature stability and mechanical strength. 90 WMoNiFe alloy sprue bushing is designed to meet these requirements.

- The concept of 90 WMoNiFe alloy sprue bushing

90 WMoNiFe alloy sprue bushing is a mold component made of 90 WMoNiFe alloy material, which is used to guide the molten material from the nozzle of the injection molding machine or die casting machine into the mold cavity during the molding process such as injection molding and die casting. The design and installation of the sprue bushing plays a key role in ensuring the quality of the molded products, improving production efficiency and extending the service life of the mold.

- Characteristics of 90 WMoNiFe alloy sprue bushing

High temperature stability

90 WMoNiFe alloy can maintain the stability of its structure and performance at high temperatures, so it is suitable for high temperature working environments. This enables the gate bushing to operate stably for a long time under the high temperature impact of the molten material.

Wear resistance

Due to the high-speed flow and impact of the molten material in the gate bushing, the material is required to have good wear resistance. The high hardness and good wear resistance of 90 WMoNiFe alloy enable it to meet this requirement, effectively reduce wear and extend service life.

Good thermal conductivity

The molten material will generate a lot of heat in the gate bushing, requiring the material to have good thermal conductivity. The high thermal conductivity of 90 WMoNiFe alloy can effectively conduct the heat away, reduce the working temperature and reduce thermal stress.

High strength and toughness

The gate bushing needs to withstand the high pressure and impact of the molten material, requiring the material to have high strength and good toughness. The high strength and high toughness of 90 WMoNiFe alloy can ensure that the gate bushing can still maintain stability and reliability in harsh working environments.

Easy to process and repair

90 WMoNiFe alloy has good processability and weldability, which is convenient for manufacturing and repair. This makes the production and replacement of the gate bushing more convenient, reducing production costs and maintenance costs.

- Advantages of 90 WMoNiFe alloy gate bushing

Improve molding quality

The high precision and wear resistance of 90 WMoNiFe alloy gate bushing can ensure the uniform flow and precise injection of molten material into the cavity, thereby improving the quality and precision of molded products.

Extend mold service life

Due to the excellent wear resistance and high temperature stability of 90 WMoNiFe alloy gate bushing, it can effectively reduce the wear and damage of the mold, thereby extending the service life of the mold.

Improve production efficiency

The excellent performance of 90 WMoNiFe alloy gate bushing can reduce the number of mold repairs and replacements, reduce the risk of production interruptions, and thus improve production efficiency.

Reduce production costs

Although the initial investment of 90 WMoNiFe alloy gate bushing may be high, due to its long life and low maintenance cost, it can effectively reduce production costs in the long run.

- Application scenarios of 90 WMoNiFe alloy gate bushing

Injection molding

During the injection molding process, the molten plastic material enters the mold cavity through the gate bushing. 90 WMoNiFe alloy gate bushing can withstand high temperature and high pressure to ensure the uniform flow and precise molding of plastic materials.

Die Casting

During the die casting process, the molten metal material flows into the mold cavity through the gate bushing. The high wear resistance and high temperature stability of the 90 WMoNiFe alloy gate bushing make it an ideal choice for die casting molds.

Other molding processes

In addition to injection molding and die casting, the 90 WMoNiFe alloy gate bushing is also suitable for other metal and non-metal molding processes, such as hot forging, hot stamping, etc.

- Professional terms and data of 90 WMoNiFe alloy gate bushing

Chemical composition

The chemical composition of the 90 WMoNiFe alloy gate bushing plays a decisive role in its performance. The common composition range is: W 20-30%, Mo 20-30%, Ni 20-30%, Fe balance. The specific composition ratio will be adjusted according to the specific application requirements.

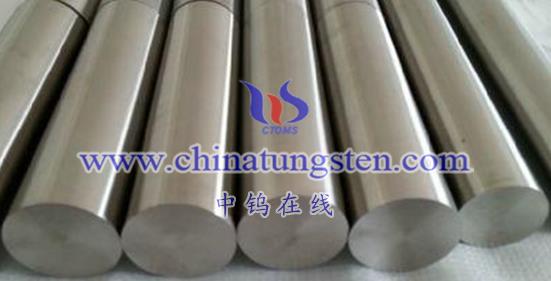

Physical properties

Physical properties such as density, thermal expansion coefficient, thermal conductivity, etc. have an important influence on the working performance of the gate bushing. For example, the density is usually between 10-12 g/cm³, the thermal expansion coefficient is low, and the thermal conductivity is high, which helps to achieve good thermal stability and wear resistance.

Mechanical properties

The mechanical properties of 90 WMoNiFe alloy sprue bushings include tensile strength, yield strength, elongation, impact toughness, etc. These performance indicators are crucial to evaluating the performance of the alloy under specific working conditions. For example, the tensile strength may reach more than 1500 MPa, and the yield strength may also exceed 1000 MPa, showing its excellent load-bearing capacity.

Wear resistance data

Wear resistance is one of the key properties of sprue bushings. Wear tests such as sliding wear test and impact wear test can be used to evaluate the wear resistance of 90 WMoNiFe alloy sprue bushings. These tests can simulate the wear conditions in the actual working environment and obtain the wear resistance data of the alloy. Generally speaking, the wear resistance of 90 WMoNiFe alloy is better than many other metal materials, and its wear rate is low, which can maintain a small amount of wear in long-term use.

High temperature performance data

For the high temperature stability of 90 WMoNiFe alloy sprue bushings, high temperature tensile tests, high temperature creep tests, etc. will be carried out. These tests can evaluate the mechanical properties and stability of the alloy under high temperature conditions. For example, in a high temperature environment above 1000℃, 90 WMoNiFe alloy can still maintain good mechanical properties and stability, ensuring that the gate bushing will not soften or fail in a high temperature working environment.

- Manufacturing process of 90 WMoNiFe alloy gate bushing

Material preparation

According to the predetermined composition ratio, metal raw materials such as tungsten, molybdenum, nickel, and iron are mixed and smelted to prepare ingots or powders of 90 WMoNiFe alloy.

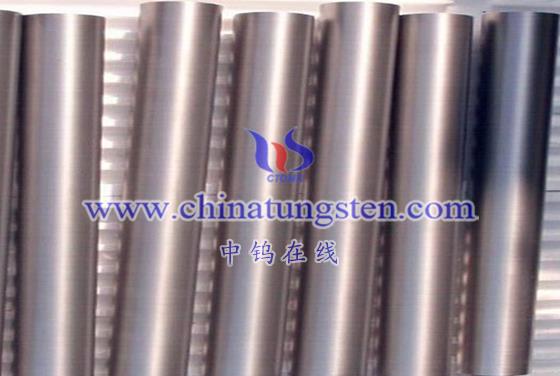

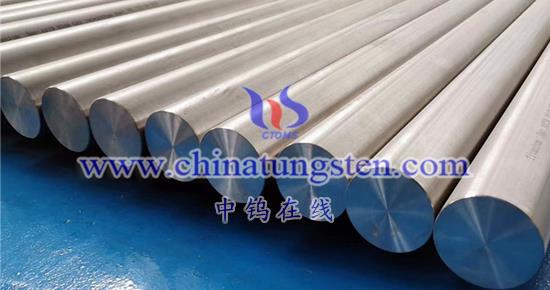

Processing and molding

The prepared 90 WMoNiFe alloy material is processed into the required shape and size of the gate bushing by mechanical processing means such as turning, milling, and drilling.

Heat treatment

The processed gate bushing is heat treated, and the structure and properties of the material are adjusted by controlling parameters such as heating temperature, insulation time, and cooling rate to improve its wear resistance, strength, and hardness.

Surface treatment

According to needs, the surface of the gate bushing is polished, sprayed, etc. to improve its wear resistance and corrosion resistance.

Assembly and debugging

Assemble the manufactured gate bushing into the mold, debug and test it to ensure that its working performance and precision meet the requirements.

VII. Development trend of 90 WMoNiFe alloy gate bushing

With the continuous development of molding technology and the improvement of product quality requirements, 90 WMoNiFe alloy gate bushings are also constantly improving and optimizing. Future development trends mainly include:

Material optimization

By further optimizing the alloy composition and preparation process, the wear resistance, high temperature stability and mechanical strength of 90 WMoNiFe alloy gate bushings are improved to meet more stringent working environments and use requirements.

Structural innovation

According to specific application scenarios and molding requirements, a more reasonable and efficient gate bushing structure is designed to improve molding quality and production efficiency.

Intelligent manufacturing

With the help of advanced manufacturing technology and intelligent equipment, the automated and precise manufacturing of 90 WMoNiFe alloy gate bushings is realized to improve production efficiency and reduce costs.

Environmental protection and sustainable development

While meeting product performance and service life, attention is paid to the environmental protection and sustainable development of materials, and the green manufacturing and recycling of 90 WMoNiFe alloy gate bushings are promoted.

As a high-performance mold component, 90 WMoNiFe alloy sprue bushing has broad application prospects in the fields of metal forming and non-metal forming. By deeply understanding its concepts, characteristics, advantages, application scenarios, and related professional terms and data, we can better understand its importance and application value in the industrial field. With the continuous advancement of science and technology and the growing demand for industry, 90 WMoNiFe alloy sprue bushings will continue to play an important role and continue to innovate and develop, making greater contributions to the sustainable development of the industrial field.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595