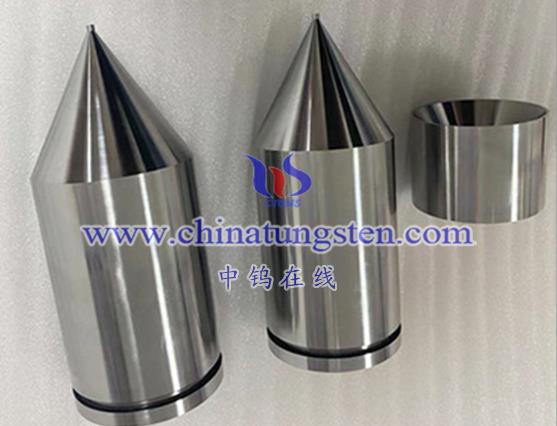

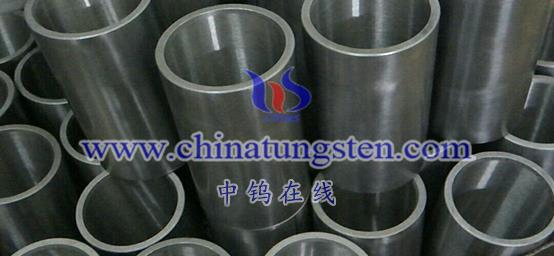

90 WMoNiFe alloy gate bushings have the following advantages in the injection molding process:

High temperature stability

During the injection molding process, the temperature of the molten plastic material is usually high, and the 90 WMoNiFe alloy gate bushings can maintain the stability of their structure and performance at high temperatures. This enables the gate bushing to withstand the high temperature impact of the molten plastic and ensure the smooth progress of the injection molding process.

Strong wear resistance

During the injection molding process, the molten plastic will generate high-speed flow and impact when passing through the gate bushing, which is easy to cause wear. However, the high hardness and wear resistance of 90 WMoNiFe alloy enable the gate bushing to resist this wear, extend its service life, reduce the frequency of replacement, and reduce production costs.

Accurately control the flow of molten plastic

The 90 WMoNiFe alloy gate bushings have high precision and excellent wear resistance, which can ensure the uniform flow and precise injection of molten plastic into the mold cavity. This helps to improve the quality and precision of injection molded products, reduce the defective rate, and improve production efficiency.

High strength and pressure resistance

During the injection molding process, the molten plastic will exert a large pressure on the gate bushing. The high strength and good mechanical properties of 90 WMoNiFe alloy enable it to withstand this pressure, maintain the stability and reliability of the gate bushing, and reduce the risk of deformation or damage.

Easy to clean and maintain

The 90 WMoNiFe alloy gate bushing has good machinability and weldability, which is convenient for cleaning and maintenance. During the injection molding process, the molten plastic may adhere to the surface of the gate bushing, but it can be removed by simple cleaning methods to keep the gate bushing clean and in good working condition.

90 WMoNiFe alloy gate bushing has the advantages of high temperature stability, strong wear resistance, precise control of molten plastic flow, high strength and pressure resistance, and easy cleaning and maintenance in the injection molding process. These advantages help to improve the quality and production efficiency of injection molded products, reduce production costs and maintenance costs, and are an ideal choice in the injection molding process.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595