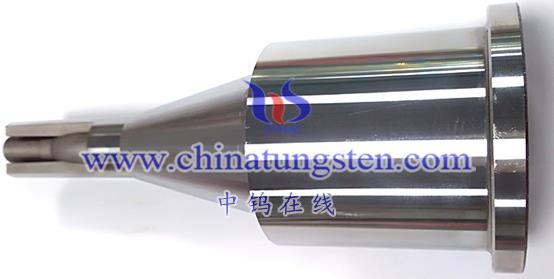

As a high-performance mold component, the 90 WMoNiFe alloy gate column plays a vital role in the field of metal forming and non-metal forming. It is made of tungsten, molybdenum, nickel, iron and other metal elements through a specific alloying process, and has excellent high temperature stability, wear resistance, mechanical strength and good thermal conductivity.

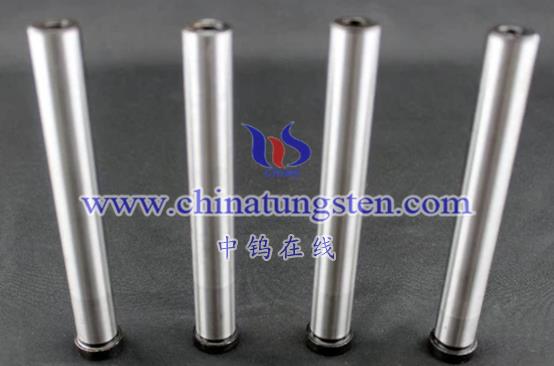

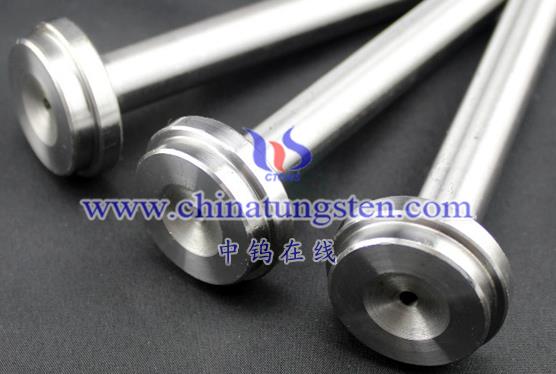

What is a gate column

The gate column is usually located at the gate of the mold and is the key channel for the molten material to flow into the mold cavity. The 90 WMoNiFe alloy gate column is a gate column made of a specific material, 90 WMoNiFe alloy, to adapt to harsh working environments such as high temperature, high pressure and high wear.

Features and advantages of 90 WMoNiFe alloy gate column

High temperature stability

90 WMoNiFe alloy has an extremely high melting point and can maintain structural stability and performance reliability at high temperatures exceeding 1000°C, ensuring the long-term stable operation of the gate column in a high temperature working environment.

Excellent wear resistance

Due to the extremely high hardness of tungsten and molybdenum, the 90 WMoNiFe alloy formed after alloying has excellent wear resistance. This allows the gate column to maintain a small amount of wear and extend its service life when it is subjected to the high-speed flow and impact of molten materials.

High strength and toughness

The addition of nickel and iron enhances the strength and toughness of the alloy, allowing the gate column to withstand greater pressure and impact without deformation or breakage.

Good thermal conductivity

90 WMoNiFe alloy has excellent thermal conductivity, which can quickly conduct the heat generated by the molten material, reduce the working temperature of the gate column, and reduce thermal stress and thermal damage.

Application scenarios of 90 WMoNiFe alloy gate column

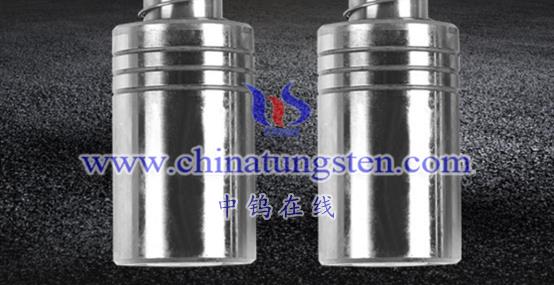

90 WMoNiFe alloy gate column is widely used in various molding processes that require high temperature, high pressure and high wear resistance, such as injection molding, die casting, continuous casting, etc. These processes usually involve molten metal or non-metallic materials, and require the gate column to withstand extremely high temperatures and pressures and maintain stable operation for a long time.

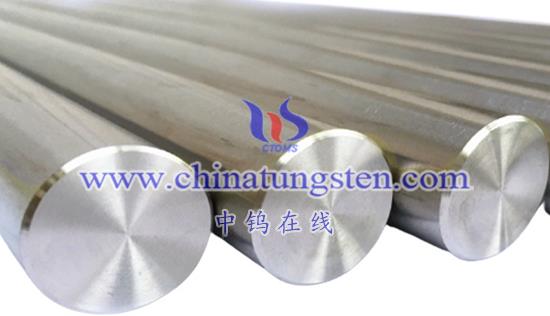

Manufacturing process of 90 WMoNiFe alloy gate column

The manufacturing process of 90 WMoNiFe alloy gate column includes material preparation, molding, heat treatment, surface treatment and other steps. First, according to the predetermined composition ratio, metal raw materials such as tungsten, molybdenum, nickel, and iron are mixed and smelted to prepare alloy materials. Then, the alloy material is processed into the required shape and size of the gate column by casting, forging or machining. Next, the organization and properties of the material are adjusted by heat treatment to improve its wear resistance, strength and hardness. Finally, surface treatment such as spraying and polishing is performed to improve the wear resistance and corrosion resistance of the gate column.

Development trend of 90 WMoNiFe alloy gate column

With the continuous development of molding technology and the improvement of product quality requirements, 90 WMoNiFe alloy gate columns are also constantly improving and optimizing. Future development trends include material optimization, structural innovation, intelligent manufacturing, and environmentally friendly and sustainable development. By optimizing the alloy composition and preparation process, the wear resistance, high temperature stability and mechanical strength of the gate column can be further improved; by designing a more reasonable and efficient gate column structure, the molding quality and production efficiency can be improved; with the help of advanced manufacturing technology and intelligent equipment, the gate column can be automated and precisely manufactured; focusing on the environmental protection and sustainable development of materials, the green manufacturing and recycling of 90 WMoNiFe alloy gate columns can be promoted.

Material performance parameters of 90 WMoNiFe alloy gate column

Melting point

The melting point of 90 WMoNiFe alloy is usually over 1500℃, ensuring that the gate column will not soften or deform in a high temperature environment.

Hardness

The Vickers hardness (HV) can usually reach over 500, ensuring that the gate column has excellent wear resistance.

Thermal expansion coefficient

A smaller thermal expansion coefficient means that the dimensional stability of the gate column is higher when the temperature changes.

Thermal conductivity

High thermal conductivity allows the gate column to dissipate heat more effectively and reduce thermal stress.

Electrical conductivity

In some applications, electrical conductivity is also an important parameter that affects the electromagnetic properties of the gate column.

Chemical stability

90 WMoNiFe alloy has good stability to many chemical media and can resist corrosion.

Design and manufacture of 90 WMoNiFe alloy gate column

Geometry

The geometry of the gate column needs to be designed according to the specific application and process conditions to ensure smooth flow and uniform distribution of the molten material.

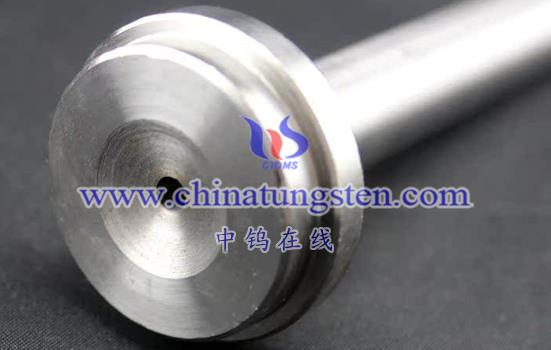

Dimensional accuracy

The dimensional accuracy of the gate column is high to ensure the matching accuracy with other parts of the mold to avoid leakage and poor molding.

Surface roughness

The surface roughness of the gate column has an important influence on the flow and adhesion of the molten material, so appropriate surface treatment is required.

Heat treatment and post-treatment

Heat treatment is a key step in adjusting the performance of the gate column, including homogenization, annealing, quenching and other processes. Post-treatment such as sandblasting and polishing can further improve the surface quality.

Application case analysis of 90 WMoNiFe alloy gate column

Specific application cases can cover multiple fields such as automobile manufacturing, aerospace, electronics and electrical appliances. In these cases, it can be analyzed how 90 WMoNiFe alloy gate columns meet specific process requirements, such as high temperature stability, wear resistance, corrosion resistance, etc.

Market Trends and Prospects of 90 WMoNiFe Alloy Gate Columns

Analyze the current market size, growth rate, major manufacturers, application fields, etc. of 90 WMoNiFe alloy gate columns, and predict future market trends and development prospects. At the same time, explore the challenges and opportunities facing the industry, such as technological innovation, environmental protection requirements, market competition, etc.

The advantages, application scenarios and market prospects of 90 WMoNiFe alloy gate pillars are summarized, and the future development direction is prospected. The importance and potential of key areas such as material optimization, structural innovation, intelligent manufacturing and environmentally friendly sustainable development are emphasized.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595