The production process of 90 WMoNiFe high entropy alloy usually includes the following main steps:

Raw material preparation

First, metal raw materials such as tungsten, molybdenum, nickel and iron need to be prepared. These raw materials are usually in the form of powder or block, and need to undergo strict quality control to ensure that the purity and proportion of the elements meet the design requirements.

Batching and mixing

According to the alloy composition design, various metal raw materials are batched in a certain proportion. Then, the raw materials are mixed evenly through high-energy ball milling, mechanical stirring or plasma spraying to ensure the uniform distribution of each element in the alloy.

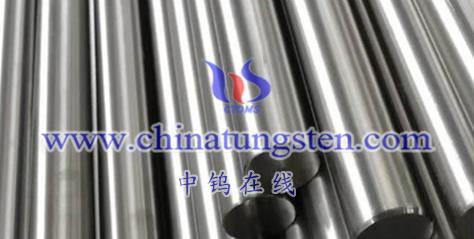

Molding

The uniformly mixed alloy powder or molten alloy is molded. The molding method can be pressing, casting, rolling, forging, etc. The specific choice depends on the shape and size requirements of the alloy.

Heat treatment

The formed alloy needs to be heat treated to improve its structure, enhance performance and eliminate internal stress. The heat treatment process usually includes steps such as solution treatment and aging treatment. Parameters such as temperature, time and cooling rate need to be precisely controlled according to the specific requirements of the alloy.

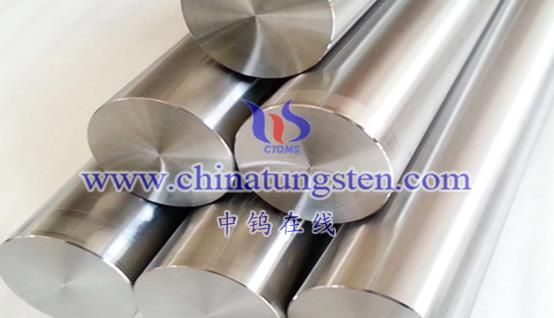

Processing and post-processing

The heat-treated alloy may require further processing and post-processing, such as cutting, grinding, polishing, etc., to meet the size and surface quality requirements of the final product.

Quality Inspection

Finally, the produced 90 WMoNiFe high-entropy alloy is subjected to quality inspection, including chemical composition analysis, mechanical properties testing, metallographic structure observation, etc., to ensure that the product quality meets the design requirements.

The production process of 90 WMoNiFe high entropy alloy is relatively complex and requires high-precision equipment and process control. In addition, due to the high requirements for the composition and performance of the alloy, multiple adjustments and optimizations may be required during the production process to obtain the best performance and cost-effectiveness.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595