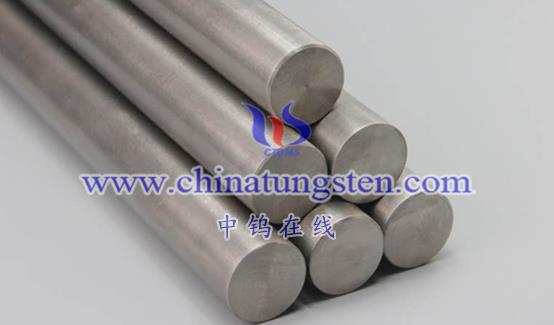

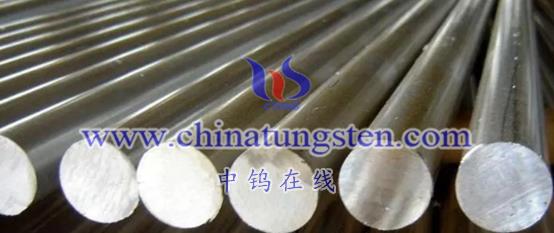

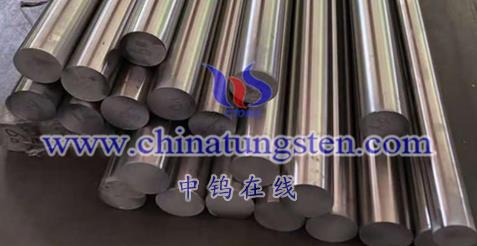

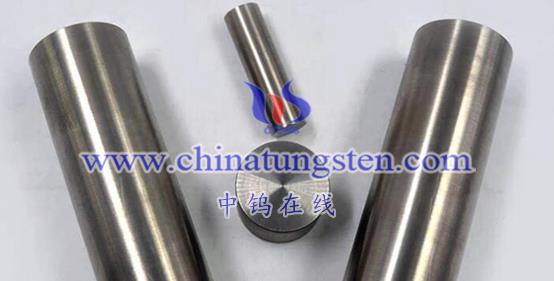

90 WMoNiFe alloy is a high-performance alloy that combines the advantages of multiple elements such as tungsten, molybdenum, nickel and iron. This alloy has a wide range of applications in many fields due to its unique physical and chemical properties. The following is a detailed analysis of the uses of 90 WMoNiFe alloy, covering multiple fields and application scenarios.

Radiation protection and guidance

90 WMoNiFe alloy has important applications in the field of radiation protection and guidance due to its high density and excellent radiation absorption ability. The radiation absorption coefficient of this alloy is 1/3 higher than that of lead, making it an ideal material for radiation shielding and protection. In medical, scientific research and industrial applications, it is necessary to prevent radiation from damaging the human body and equipment. The high radiation absorption ability of 90 WMoNiFe alloy makes it an ideal choice for these scenarios.

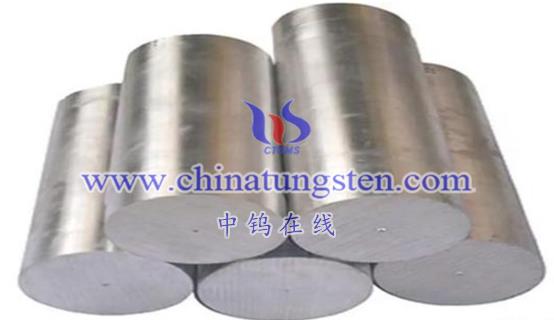

Industrial counterweight components

Due to its extremely high density (about 18.8g/cm³), 90 WMoNiFe alloy is also widely used in the field of industrial counterweight components. The high density of this alloy makes it an ideal material for manufacturing industrial counterweight components such as counterweights and balance hammers. In the fields of heavy machinery, aerospace, ships, etc., these counterweight components are essential to ensure the stable operation and safety of equipment.

Safety and defense components

Due to its high strength, corrosion resistance and high temperature stability, 90 WMoNiFe alloy is also widely used in the field of safety and defense components. For example, in the military field, this alloy can be used to manufacture bulletproof plates, tank armor and other defense devices to effectively resist external impact and attack. In the civilian field, it can also be used to manufacture safety facilities such as safety doors and explosion-proof windows to protect people’s lives and property.

Nuclear power and energy components

Due to its excellent corrosion resistance and high temperature stability, 90 WMoNiFe alloy is also important in the field of nuclear power and energy. This alloy can be used to manufacture key components such as heat exchangers, pipes and valves in nuclear reactors, and can withstand harsh environments of high temperature, high pressure and strong corrosion. In addition, in the field of new energy such as solar energy and wind energy, this alloy can also be used to manufacture energy storage devices, solar panel brackets and other components.

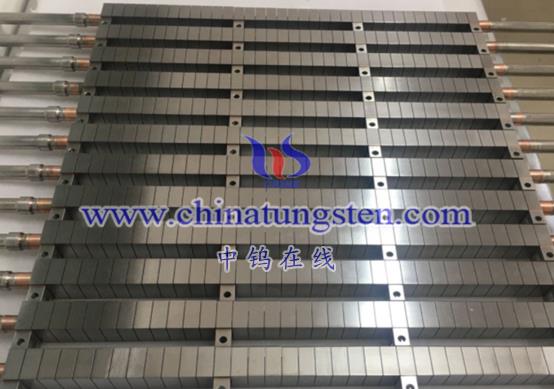

Tungsten alloy for die casting

90 WMoNiFe alloy is also widely used in the field of die casting. Due to its high density and good mechanical properties, this alloy can be used to manufacture die casting molds, die castings and other components. In industries such as automobiles, motorcycles, and home appliances, these components are essential to ensure the quality and performance of products.

Hot-riveted bearing materials

90 WMoNiFe alloy is also used in the field of hot-riveted bearing materials due to its good high-temperature performance and wear resistance. This alloy can be used to manufacture high-temperature bearings, anvils and other components, and can withstand the harsh environment of high temperature and high-speed operation. In the fields of aerospace, automobiles, energy, etc., these components are of great significance to ensure the normal operation of equipment and extend its service life.

Hot stamping valves

In addition, 90 WMoNiFe alloy is also used in the field of hot stamping valves. This alloy has high thermal conductivity and good red hardness, and can maintain good mechanical properties at high temperatures. Therefore, it can be used to manufacture parts such as electric anvils for valve stamping, improving the service life and working efficiency of the anvils.

Chemical and petroleum industries

90 WMoNiFe alloy is also widely used in the chemical and petroleum industries. Due to its excellent corrosion resistance and high temperature stability, this alloy can be used to manufacture corrosion-resistant containers, pipes, valves and other components. In the chemical production process, these components can withstand the erosion of various highly corrosive media to ensure the smooth progress of the production process. In the petroleum industry, this alloy can also be used to manufacture oil drill bits and other mining equipment to improve the wear resistance and service life of the equipment.

Aerospace field

90 WMoNiFe alloy also has important applications in the aerospace field. Due to its high strength, high temperature stability and good corrosion resistance, this alloy can be used to manufacture engine parts, combustion chambers and missile aircraft components. In the aerospace field, these parts need to withstand extreme high temperature, high pressure and strong corrosion and other harsh environments. The excellent properties of 90 WMoNiFe alloy make it an ideal choice for these application scenarios.

Shipbuilding and marine engineering

90 WMoNiFe alloy is also widely used in the field of shipbuilding and marine engineering. Since this alloy can resist seawater corrosion and mechanical wear, it is often used to manufacture key components such as propellers, shaft systems, and thrusters of ships. In addition, in marine engineering activities such as deep-sea drilling and seabed resource mining, this alloy can also be used to manufacture corrosion-resistant pipes, joints, and valves.

Electronics and communications

90 WMoNiFe alloy is also used in the electronics and communications fields due to its excellent electrical conductivity and high-temperature stability. This alloy can be used to manufacture connectors, contact pieces and other components of electronic equipment to ensure stable current transmission. In addition, in the communications field, this alloy can also be used to manufacture high-frequency electronic devices and microwave devices, etc., to meet the high requirements of communication equipment for material performance.

Medical devices and biomedical fields

90 WMoNiFe alloys are also used in medical devices and biomedical fields. Due to its good biocompatibility, corrosion resistance and strong wear resistance, this alloy can be used to manufacture medical devices such as surgical instruments, dental instruments, etc. In addition, in the biomedical field, this alloy can also be used to manufacture biosensors, drug carriers, etc., providing strong support for medical research and treatment.

Sports equipment and automobile manufacturing

90 WMoNiFe alloy is also widely used in the fields of sports equipment and automobile manufacturing. The high density and good mechanical properties of this alloy make it an ideal material for manufacturing sports equipment such as golf clubs and bicycle frames. In the field of automobile manufacturing, this alloy can be used to manufacture key components such as engine parts and brake systems to improve the performance and safety of automobiles.

Artwork and jewelry making

In addition to the above fields, 90 WMoNiFe alloy also has unique applications in the field of art and jewelry making. The high density and unique metallic luster of this alloy make it an ideal material for making high-end jewelry and artworks. Through exquisite craftsmanship and unique design, 90 WMoNiFe alloy can create artworks and jewelry works with unique beauty and value.

In summary, 90 WMoNiFe alloys are widely used in many fields, including shipbuilding and marine engineering, electronics and communications, medical equipment and biomedicine, sports equipment and automobile manufacturing, as well as artwork and jewelry making. With its unique physical and chemical properties, this alloy meets the high requirements for material performance in different fields and provides strong support for the development of various industries. With the advancement of science and technology and the expansion of the market, the application areas of 90 WMoNiFe alloys will continue to expand and deepen.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595