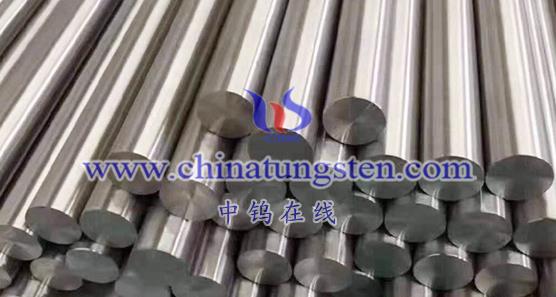

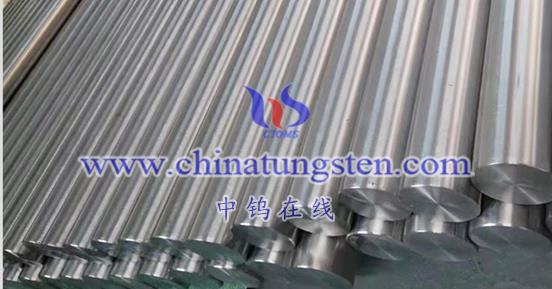

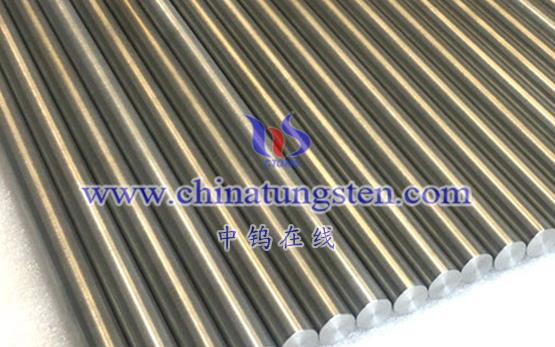

90WMoNiFe alloy rods are an alloy material with special properties. It combines the advantages of metals such as tungsten, molybdenum, nickel and iron, so that it can show excellent performance in extreme environments such as high temperature, high pressure and corrosion resistance. There are many types of this alloy rod, which can be divided into the following categories according to different application requirements and manufacturing processes:

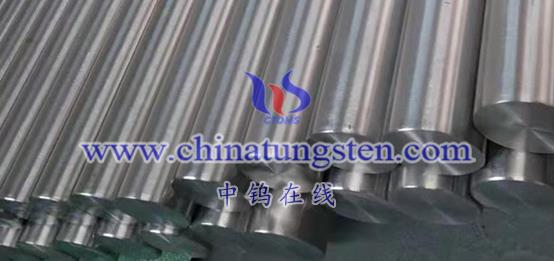

High-temperature alloy rods

This type of alloy rod is mainly used for work in high-temperature environments, such as aerospace engines, gas turbines and other fields. They have excellent high-temperature strength and oxidation resistance, and can maintain stable performance at high temperatures for a long time.

Corrosion-resistant alloy rods

This type of alloy rod has excellent corrosion resistance and is suitable for occasions working in corrosive media such as acids, alkalis and salts. They are widely used in chemical industry, marine engineering and other fields.

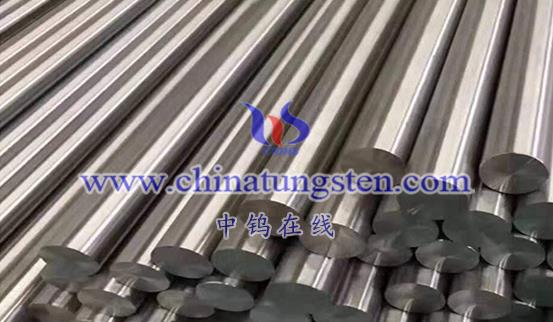

High-strength alloy rods

This type of alloy rod is characterized by high strength and high toughness, and is suitable for occasions that need to withstand high loads and impact forces. They are widely used in machinery, automobiles and other fields.

In addition, according to the specific alloy composition and manufacturing process, more types of 90WMoNiFe alloy rods can be subdivided to meet the needs of different fields. When selecting and using this type of alloy rod, it is necessary to select the appropriate alloy type and specification according to the specific application scenarios and requirements.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595