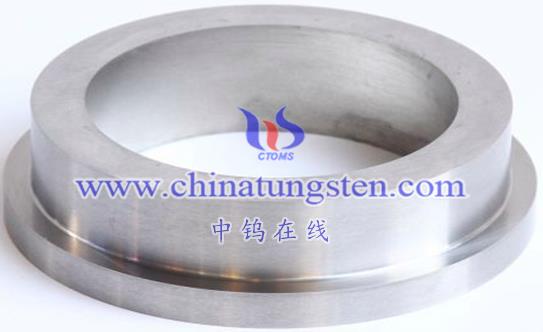

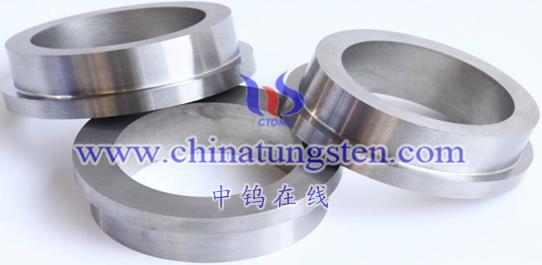

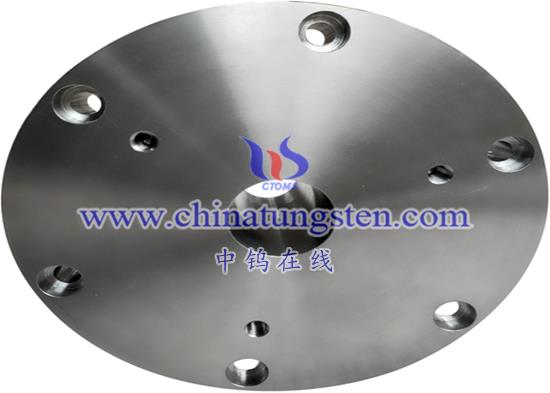

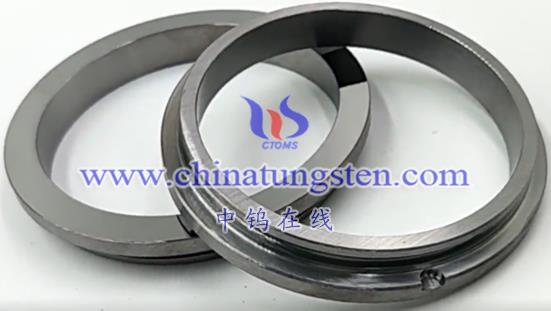

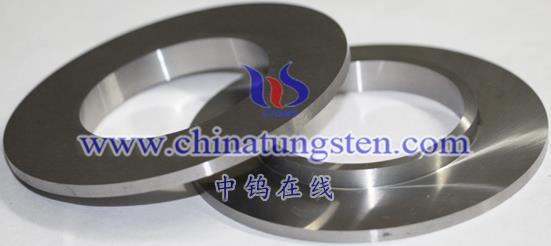

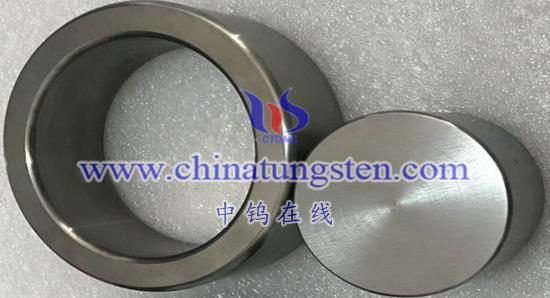

As a high-performance sealing element, 90WMoNiFe alloy sealing rings have a series of advantages, but also some possible disadvantages. The following is a detailed analysis of its advantages and disadvantages:

Advantages of 90WMoNiFe alloy sealing rings:

Excellent high temperature resistance

90WMoNiFe alloy has a high melting point and can maintain structural stability at extremely high temperatures. It is very suitable for high-temperature working environments, such as metallurgy, petrochemicals and other fields.

Good corrosion resistance

The alloy has good corrosion resistance for a variety of chemical media and can be used for a long time in corrosive environments such as acids and alkalis without being significantly corroded.

Excellent strength and hardness

The alloy has high strength and hardness, which enables it to maintain good sealing performance under high pressure and complex working conditions.

Good thermal conductivity

90WMoNiFe alloy has good thermal conductivity, which can effectively conduct heat away, reduce the temperature of working parts and improve the stability of equipment.

Good wear resistance

During long-term friction, the wear degree of 90WMoNiFe alloy is relatively low, which can ensure the long-term stability of the sealing ring.

Disadvantages of 90WMoNiFe alloy sealing rings:

High cost

Due to the relatively high prices of metal elements such as tungsten, molybdenum, nickel, and iron, the manufacturing cost of 90WMoNiFe alloy sealing rings is also high, which increases the purchase cost of equipment.

High processing difficulty

The high hardness of 90WMoNiFe alloys makes it difficult to process and cut, and special processes and equipment are required for processing.

Relatively large brittleness

Although the alloy has high hardness and strength, it is also more brittle than some materials and may break under specific working conditions.

90WMoNiFe alloy sealing rings have a wide range of application value in multiple industrial fields due to their high temperature resistance, corrosion resistance, high strength and excellent wear resistance, but they also have the problems of high cost and difficulty in processing. When choosing to use, it is necessary to weigh the specific working environment and needs.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595