Tungsten-molybdenum alloy is mainly composed of two metal elements, tungsten and molybdenum, and has a series of unique characteristics, which makes it widely used in many fields. The following are the main characteristics of tungsten-molybdenum alloy:

High melting point and high stability

Both tungsten and molybdenum are high-melting-point metals. The melting point of tungsten is as high as 3422℃, while the melting point of molybdenum is also quite high, reaching 2620℃. This enables tungsten-molybdenum alloy to maintain good stability in high-temperature environments and is not easy to melt or lose mechanical properties. Therefore, tungsten-molybdenum alloy is often used as a raw material for high-temperature equipment and tools, such as aerospace engine nozzles, high-temperature furnace internal components, etc.

High density

The density of tungsten is as high as 19.25 g/cm3, while the density of molybdenum is also quite large, at 10.22 g/cm3. This high density makes tungsten-molybdenum alloy have excellent radiation blocking ability, which can effectively prevent the penetration of X-rays and gamma rays, so it is widely used in medical equipment, nuclear energy fields, and radiation protection materials.

Good corrosion resistance

Both tungsten and molybdenum are precious metals with good corrosion resistance. Tungsten-molybdenum alloys can resist many common corrosive media, including acid and alkali solutions, seawater, chlorine, etc., and are not prone to oxidation reactions.

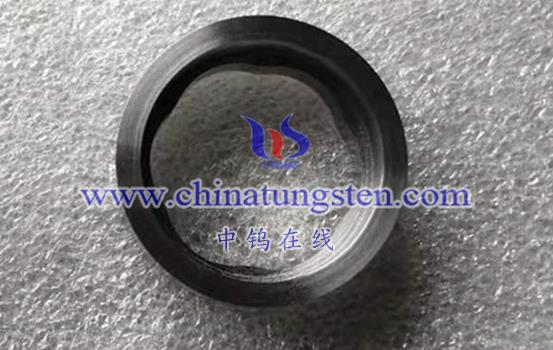

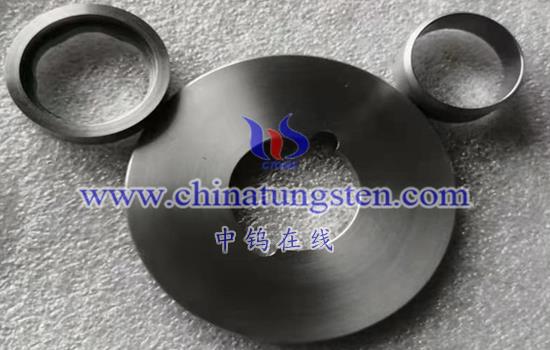

High strength and good wear resistance

Tungsten-molybdenum alloys have high tensile strength and yield strength, as well as excellent wear resistance, making them suitable for applications that require high mechanical properties and wear resistance.

Low thermal expansion coefficient

Tungsten-molybdenum alloys have a low thermal expansion coefficient, which means that they can still maintain good dimensional stability in high temperature environments, which is particularly important for some applications that require high precision.

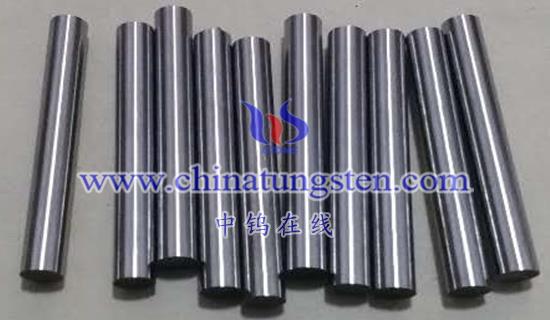

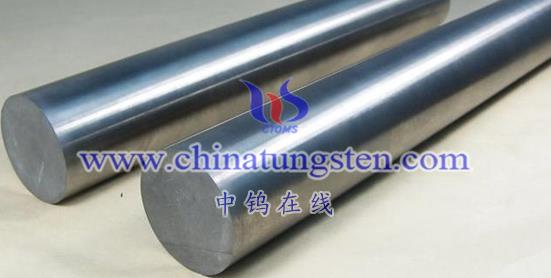

Good processing performance

Tungsten-molybdenum alloys can be manufactured into parts of various shapes and sizes through a variety of processing methods such as casting, forging, and rolling, and their welding and coating properties are also quite good.

In summary, tungsten-molybdenum alloys have been widely used in aerospace, military, industry and other fields due to their high melting point, high density, good corrosion resistance, high strength, low thermal expansion coefficient and good processing performance.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595