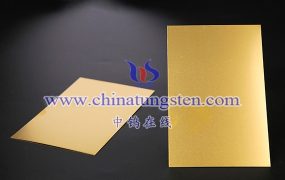

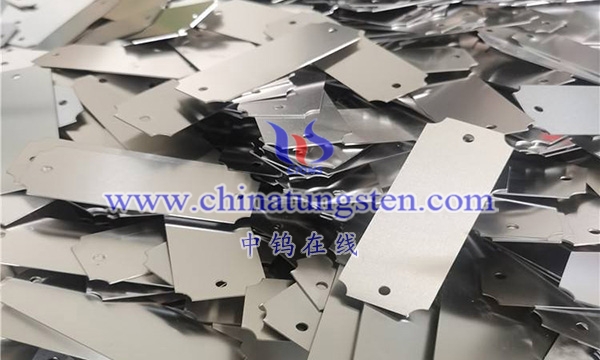

CuW heat sink is a composite material composed of tungsten and copper. Tungsten is a metal element with high melting point and high hardness, with good thermal conductivity and mechanical properties. Copper is a good electrical conductor with good processing performance and corrosion resistance. By mixing tungsten and copper in a certain proportion, a CuW heat sink with excellent performance can be prepared.

The manufacturing process of CuW heat sink mainly includes batching, mixing, pressing, sintering and processing. Among them, batching and mixing are the key steps in the manufacture of CuW heat sinks. It is necessary to ensure that the mixing ratio of tungsten and copper is uniform to ensure the stable performance of the material. Pressing is to put the mixed tungsten copper powder into the mold, apply pressure through the pressing equipment, so that the powder is tightly combined and formed into a blank of the desired shape. Sintering is to put the pressed blank into the sintering furnace and sinter it at high temperature, so that the interface between tungsten and copper diffuses and reacts to form a strong metallurgical bond. Processing is to cut, grind, polish and other processes on the sintered tungsten copper alloy to obtain precise size and surface finish.

More details of Tungsten Copper Heat Sinks, please visit website: http://tungsten-copper.com/Tungsten-Copper-Heat-Sink.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595