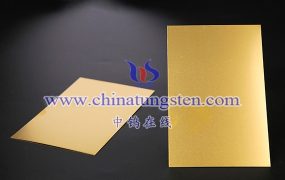

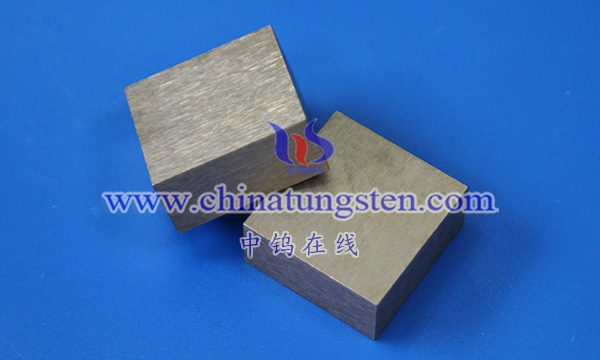

Copper tungsten heat sink is an electronic component packaging material with excellent performance, and has the advantages of high thermal conductivity, high electrical conductivity, high strength and good corrosion resistance. It has a wide range of applications in the field of electronic component packaging. The following will introduce the application of copper tungsten heat sinks in detail.

1. Overview

Copper tungsten heat sink composed of tungsten and copper. Tungsten is a metal element with high melting point and high hardness, and has good thermal conductivity and mechanical properties. Copper is a good electrical conductor with good processing performance and corrosion resistance. By mixing tungsten and copper in a certain proportion, a copper tungsten heat sink with excellent performance can be prepared.

2. Application field

1. High-power electronic devices

In high-power electronic devices, copper tungsten heat sinks are widely used in heat dissipation and heat conduction structures. Since high-power electronic devices generate a lot of heat when working, if the heat is not properly controlled, it will cause the device performance to deteriorate or even be damaged. Copper tungsten heat sink has high thermal conductivity and high strength, which can effectively conduct heat away, reduce the operating temperature of the device, and improve its stability and reliability.

In some high-power electronic devices, copper tungsten heat sink can also be used as a conductive structure to meet the electrical connection requirements of the device. This material has good conductivity and can ensure the normal operation of the device.

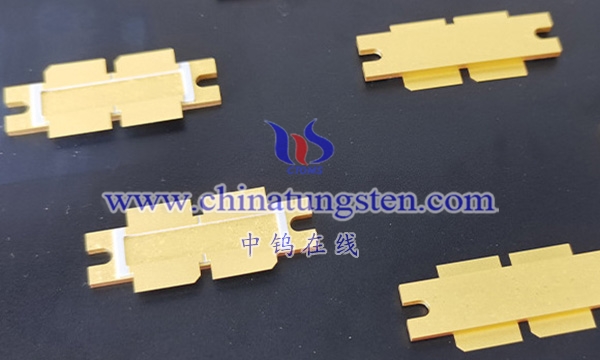

2. Microwave devices

In microwave devices, copper tungsten heat sinks are widely used in heat dissipation and electromagnetic shielding structures. Microwave devices generate high-frequency electromagnetic waves when working, and also generate a lot of heat. The high thermal conductivity and good electrical properties of copper tungsten heat sinks can ensure the normal operation of microwave devices, while avoiding performance degradation or damage caused by improper heat control.

In addition, copper tungsten heat sinks also have good electromagnetic shielding properties, which can effectively suppress electromagnetic interference and improve the stability and reliability of microwave devices.

3. Lasers

In lasers, copper tungsten heat sinks are widely used in heat dissipation and support structures. Lasers generate a lot of heat when working. If the heat is not properly controlled, the performance of the laser will be degraded or even damaged. The high thermal conductivity and good corrosion resistance of copper tungsten heat sinks can ensure the normal operation of lasers while avoiding performance degradation or damage caused by improper heat control.

In addition, copper tungsten heat sinks also have high strength and good toughness, which can withstand various stresses generated by lasers during operation and ensure the stability and reliability of components.

4. Aerospace field

In the aerospace field, electronic components need to work under extreme temperature and pressure conditions, and copper tungsten heat sinks can provide excellent thermal management and electrical connection performance to ensure the normal operation of electronic components. For example, in aircraft engine control systems, copper tungsten heat sinks are widely used in heat dissipation and heat conduction structures to ensure the stability and reliability of engine control systems.

5. National defense field

In the defense field, electronic components need to have high stability and reliability, and the high strength and good corrosion resistance of copper tungsten heat sinks can ensure the normal operation of electronic components while avoiding performance degradation or damage caused by environmental factors. For example, in missile systems, copper tungsten heat sinks are widely used in heat dissipation and support structures to ensure the stability and reliability of missile systems.

3. Summary

In summary, copper tungsten heat sinks have a wide range of applications in the field of electronic component packaging. Especially in situations where high thermal conductivity and good electrical properties are required, such as high-power electronic devices, microwave devices, lasers, etc. In addition, in high-end fields such as aerospace and national defense, the performance and reliability requirements of electronic components are extremely high, and copper tungsten heat sinks also play an important role. With the continuous development of science and technology, the application prospects of copper tungsten heat sinks will be broader.

More details of Tungsten Copper Heat Sinks, please visit website: http://tungsten-copper.com/Tungsten-Copper-Heat-Sink.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595