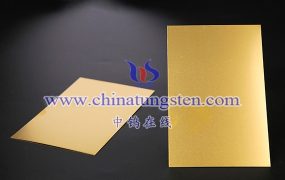

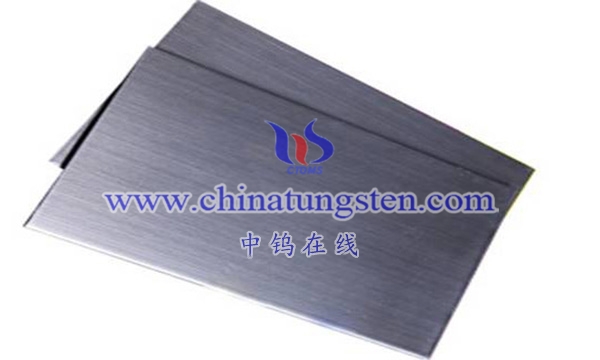

Copper tungsten heat sink is a composite material composed of tungsten and copper, with a series of excellent characteristics. The following is a detailed introduction to the characteristics of copper tungsten heat sink:

1. High thermal conductivity

Copper tungsten heat sink has high thermal conductivity and can quickly conduct the heat generated by electronic components. Compared with traditional pure copper packaging materials, copper tungsten heat sinks have higher thermal conductivity, which can more effectively reduce the operating temperature of electronic components and improve their stability and reliability. According to relevant data, the thermal conductivity of copper tungsten heat sinks can reach more than several times that of pure copper.

2. High electrical conductivity

Copper tungsten heat sink also has high electrical conductivity, which can meet the electrical connection requirements of electronic components. This good electrical property enables copper tungsten heat sinks to adapt to the electrical connection requirements of various electronic devices and ensure the normal operation of electronic components. Compared with pure copper, the electrical conductivity of copper tungsten heat sinks is also relatively high.

3. High strength and good toughness

Copper tungsten heat sink has high strength and good toughness, and can withstand various stresses generated by electronic components during operation, ensuring the stability and reliability of components. The strength and toughness of this material enable it to adapt to various complex working environments and ensure the performance and reliability of electronic components.

4. Good corrosion resistance

Copper tungsten heat sink has good corrosion resistance and can be used for a long time in harsh environments without damage. This corrosion resistance enables copper tungsten heat sink to adapt to various complex working environments and ensure the stability and reliability of electronic components. Compared with pure copper, the corrosion resistance of copper tungsten heat sink has also been significantly improved.

5. Easy to process and manufacture

Copper tungsten heat sink can be manufactured by powder metallurgy process, which has the characteristics of easy processing and manufacturing. This easy processing and manufacturing feature enables copper tungsten heat sink to meet the needs of large-scale production while reducing production costs. In addition, the shape and size of copper tungsten heat sink can also be precisely controlled through processing and manufacturing processes to meet various different application requirements.

6. Environmentally friendly and harmless

The tungsten-copper alloy encapsulated heat sink material does not contain toxic and harmful substances, does not pollute the environment, and meets environmental protection requirements. This environmentally friendly and harmless characteristic makes the tungsten-copper alloy encapsulated heat sink material have broad application prospects and market potential in the field of electronic component packaging. At the same time, it also meets the requirements of modern electronic products for environmental protection and sustainable development.

7. Excellent thermal shock resistance

The tungsten-copper alloy encapsulated heat sink material also has good thermal shock resistance. This means that even under extreme temperature changes, it can maintain stable physical properties and working characteristics. This excellent thermal shock resistance enables the tungsten-copper alloy encapsulated heat sink material to adapt to various harsh working environments and ensure the performance and reliability of electronic components.

8. Excellent anti-oxidation performance

The tungsten-copper alloy encapsulated heat sink material also has good anti-oxidation performance. In a high temperature environment, it can effectively resist oxidation corrosion and maintain its original physical properties and working characteristics. This excellent anti-oxidation performance enables the tungsten-copper alloy encapsulated heat sink material to work stably for a long time in a high temperature environment, providing reliable heat dissipation and electrical connection solutions for electronic components.

9. Good microwave properties

Copper tungsten heat sink also has good microwave properties and can meet the needs of high-frequency electronic equipment. In microwave devices, it can effectively suppress electromagnetic interference and improve the stability and reliability of the equipment. This good microwave property makes copper tungsten heat sink have broad application prospects in the field of microwave devices.

10. Excellent fatigue resistance

Copper tungsten heat sink also has good fatigue resistance. Under repeated stress, it can maintain stable physical properties and working characteristics, and will not experience fatigue fracture and other phenomena. This excellent fatigue resistance enables copper tungsten heat sink to adapt to various repeated stress working environments and provide reliable support and protection for electronic components.

In summary, copper tungsten heat sink has a series of excellent characteristics, such as high thermal conductivity, high electrical conductivity, high strength and good toughness, good corrosion resistance, easy processing and manufacturing, environmentally friendly, excellent thermal shock resistance, good oxidation resistance, and good microwave properties and fatigue resistance. These characteristics make copper tungsten heat sink have broad application prospects and market potential in the field of electronic component packaging.

More details of Tungsten Copper Heat Sinks, please visit website: http://tungsten-copper.com/Tungsten-Copper-Heat-Sink.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595