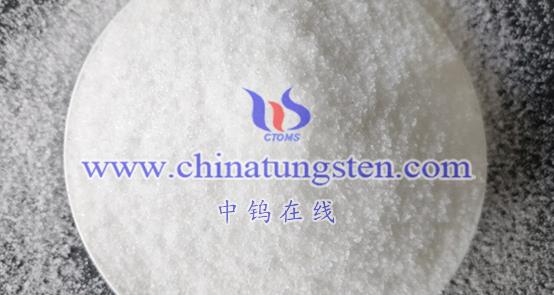

When using electrodialysis to produce ammonium metatungstate (AMT) crystals, quality control of AMT crystals is crucial. Here are some key control points and methods to ensure that the quality of the produced AMT crystals is stable and meets the requirements:

Raw material control

Ensure that the quality of the ammonium tungstate anolyte used is stable and free of impurities.

Monitor key parameters such as pH value and concentration of raw materials to ensure that they are within the appropriate range.

Electrodialysis process control

Strictly control parameters such as voltage and current density during the electrodialysis process to ensure the efficiency of ion migration and exchange.

Monitor the pH changes of the anolyte and catholyte to ensure that they are within the appropriate range to avoid the formation of insoluble compounds. According to experimental or production experience, adjust and optimize the time, temperature and other parameters of electrodialysis to obtain the best AMT crystal yield and quality.

Product recovery and purification

Before recovering AMT crystals, ensure that the anolyte is fully clarified and evaporated to remove impurities.

Monitor parameters such as temperature and stirring speed during the evaporation process to prevent crystals from being too large or too small, affecting quality.

The recovered AMT crystals can be further purified by centrifuges, filters and other equipment to remove residual impurities and solutions.

Quality inspection

The quality of the produced AMT crystals is inspected, including purity, crystallinity, particle size distribution and other indicators.

Chemical analysis, X-ray diffraction, scanning electron microscopy and other methods can be used for quality inspection.

According to the test results, timely adjust and optimize production parameters to ensure stable product quality.

Quality management system

Establish a strict quality management system to ensure that every link from raw materials to products meets quality requirements.

Train operators to improve their understanding and control of product quality.

Regularly conduct internal audits and external certifications to ensure the effectiveness of the quality management system.

Through the above control points and methods, it can be ensured that the quality of AMT crystals produced by electrodialysis is stable and meets the requirements. At the same time, based on experimental or production experience, continuous optimization of production parameters and process flow can further improve the yield and quality of AMT crystals.

In addition, it is worth noting that bipolar membrane electrodialysis, as an advanced electrodialysis technology, shows high current efficiency and low DC power consumption in the preparation of ammonium metatungstate solution. By optimizing process parameters such as current density, WO3 concentration of salt chamber solution, and initial concentration of NH4HCO3 in the alkali chamber, the efficiency and quality of preparing ammonium metatungstate solution by bipolar membrane electrodialysis can be further improved.

More details of ammonium metatungstate product, please visit website: http://ammonium-metatungstate.com/

Please contact CHINATUNGSTEN for inquiry and order of ammonium metatungstate:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595