The manufacturing process of the barium copper-based barium tungsten cathode usually involves multiple steps to ensure that the cathode material has excellent electron emission performance and stability. The following is an overview of a possible manufacturing process:

Material preparation

First, it is necessary to prepare the raw materials of barium (Ba), copper (Cu) and tungsten (W). These materials usually have specific purity requirements to ensure the performance of the cathode.

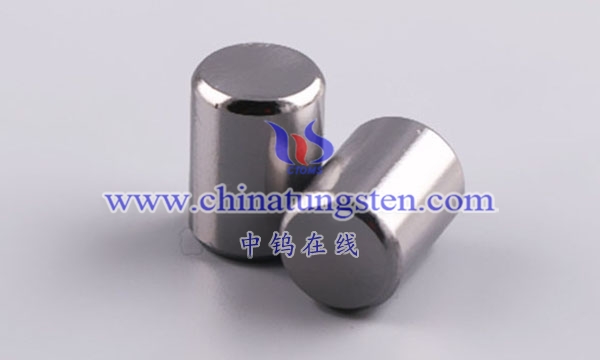

Mixing and pressing

The powders of barium, copper and tungsten are mixed evenly in a certain proportion. Then, the mixed powder is loaded into a mold and pressed to form the matrix of the cathode.

Sintering

The pressed cathode matrix is sintered at high temperature. The purpose of this step is to form a close bond between the powder particles and improve the mechanical strength and stability of the cathode.

Coating active material

A layer of active material containing barium and tungsten is coated on the surface of the sintered cathode matrix. This layer of active material is a key part of the cathode electron emission, and its quality and uniformity have an important impact on the cathode performance.

Heat treatment

The cathode coated with active material is heat treated at high temperature. The purpose of this step is to form a stable chemical bond between the active material and the cathode matrix and promote the uniform distribution of the active material.

Performance testing

Performance tests are performed on the manufactured barium copper-based barium tungsten cathode, including indicators such as electron emission performance, stability, and life. These tests will help evaluate the quality of the cathode and determine whether it meets the requirements of a specific application.

The manufacturing process of the barium copper-based barium tungsten cathode may vary depending on factors such as specific application requirements, equipment conditions, and production processes. Therefore, in the actual production process, the manufacturing process may need to be adjusted and optimized according to specific circumstances.

In addition, the process parameters of each step in the manufacturing process of the barium copper-based barium tungsten cathode need to be strictly controlled to ensure the performance and stability of the cathode. For example, in the mixing and pressing process, parameters such as the particle size, mixing ratio, and pressing pressure of the powder need to be controlled; in the sintering and heat treatment process, parameters such as temperature, time, and atmosphere need to be controlled. The adjustment of these parameters will directly affect the performance and life of the cathode.

More details of tungsten barium electrode or tungsten barium cathode, please visit website: http://tungsten.com.cn/barium-tungsten-cathode.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595