The preparation process of bombardment-resistant barium tungsten electrode usually involves multiple steps to ensure that the electrode material has excellent performance and long life. The following is a common process for preparing bombardment-resistant barium tungsten electrode:

Preparation of tungsten sponge

Raw material preparation

Use high-purity tungsten powder, paraffin, aviation gasoline and glycerol as raw materials.

Preparation process

First, pour aviation gasoline into paraffin to melt the paraffin, and then pour the melted paraffin and gasoline mixture into tungsten powder and stir quickly until the gasoline in the mixture is completely volatilized.

Molding and sintering

The stirred tungsten powder mixture is pressed into blocks, and then low-temperature sintering and high-temperature sintering are performed. During the low-temperature sintering process, the temperature is slowly increased to 600℃ before maintaining a certain heating rate; in the range of 600℃ to 1400℃, the heating rate is further increased and kept warm for a period of time. Finally, high-temperature sintering is performed, usually at around 2000℃.

Preparation of launch material

Raw material preparation

The main raw materials are barium aluminate and aluminum oxide (Al2O3).

Preparation process

Put the barium aluminate in an oven for baking, then grind and press it into blocks. Put the pressed blocks into a molybdenum boat and add alumina for sintering. During the sintering process, control different temperatures and times to obtain the desired emission material.

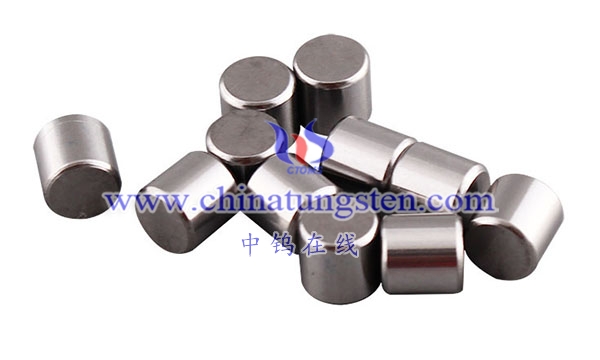

Preparation of impregnated barium tungsten electrode

Put the prepared emission material (barium aluminate) into nitrocellulose and stir it into a paste.

The paste emission material is evenly applied to the surface of the tungsten sponge.

The tungsten sponge coated with the emission material is subjected to high temperature treatment, usually at around 1750℃, until the surface color of the product turns light green.

Through the above steps, the bombardment-resistant barium tungsten electrode is prepared. This electrode has excellent characteristics such as high electron emission capability, low work function, and high electron emission electron current density, and is suitable for various occasions requiring high stability and long life. Please note that the specific preparation process may vary depending on the equipment and materials.

More details of tungsten barium electrode or tungsten barium cathode, please visit website: http://tungsten.com.cn/barium-tungsten-cathode.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595