The impregnation process of tungsten-barium cathode material is a method for preparing high-performance barium tungsten cathode. This process mainly includes the following steps:

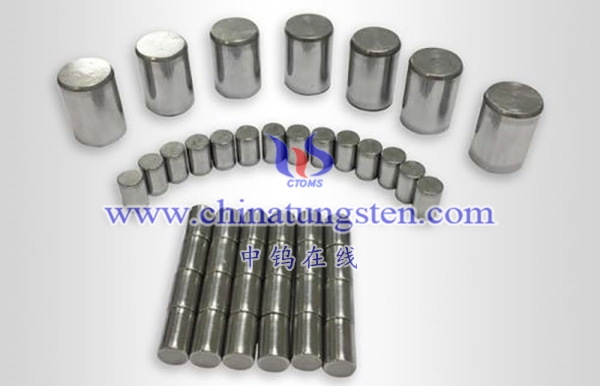

Preparation of porous tungsten matrix

It can be prepared by various methods such as organic matrix slurry drying sintering method, reaction sintering method and traditional sintering method. The traditional sintering method involves adding an alcohol solution containing glycerol and a lubricant to tungsten powder, pressing and molding after mixing evenly, and then pre-sintering and high-temperature sintering to obtain a porous tungsten matrix.

Impregnation of barium salt

Based on the obtained porous tungsten matrix, the barium salt (usually aluminate mixed in a certain proportion of BaO, CaO, and Al2O3) is melted and impregnated into the pores of the porous tungsten matrix by heating. The key to this step is to ensure that the barium salt can evenly penetrate into the pores of the matrix.

The main principle of the impregnation process of tungsten-barium cathode material is to utilize the pore structure of the porous tungsten matrix, and to fill the active substances such as barium salts into the pores evenly by impregnation to form a barium tungsten cathode with excellent electron emission performance. This cathode material is widely used in electronic devices and systems such as gas discharge lamps, high-frequency oscillators, vacuum tubes, microwave tubes, etc.

However, factors such as temperature, time and concentration of the impregnation solution need to be controlled during the impregnation process to ensure that the barium salt can evenly penetrate into the pores of the matrix and form a stable composite structure. At the same time, post-processing processes such as drying and roasting are required after impregnation to improve the performance and stability of the cathode.

More details of tungsten barium electrode or tungsten barium cathode, please visit website: http://tungsten.com.cn/barium-tungsten-cathode.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595