The barium-tungsten (Ba-W) cathode is a hot cathode that uses the porous characteristics of the tungsten matrix to store active substances in the tungsten sponge.

Under working conditions, the salt reacts with the tungsten matrix, and the reduced free barium diffuses along the pores to the cathode surface to form a stable emission. This cathode has high pulse current emission density, long service life, resistance to ion bombardment and anti-poisoning, so it is widely used in modern microwave vacuum electronic devices, such as cyclotrons, high-current linear induction accelerators, klystrons, etc., to provide a steady supply of electrons for these devices.

The performance of the barium-tungsten cathode is mainly determined by two aspects: the porous tungsten matrix and the active substance filled in the pores of the matrix-salt. When preparing a tungsten-rhenium-based barium tungsten cathode, first prepare an NH4ReO4 (ammonium perrhenate) aqueous solution, then immerse the sintered porous tungsten substrate in the solution to adsorb NH4ReO4, and then bake and sinter to convert it into a W-Re substrate, and finally immerse it in aluminate and coat it to complete the manufacturing.

In addition, barium-tungsten cathodes can also be used in other fields, such as xenon flash lamps, to make photographic lamps, electronic bayonet lamps, skin rejuvenation and hair removal beauty lamps, solar detection, pump light source lamps, pulse sterilization, industrial counting lamps, indicator lamps and signal lamps. However, the preparation process of barium-tungsten cathodes is relatively complicated, and the life of the cathode is limited, requiring regular replacement or maintenance.

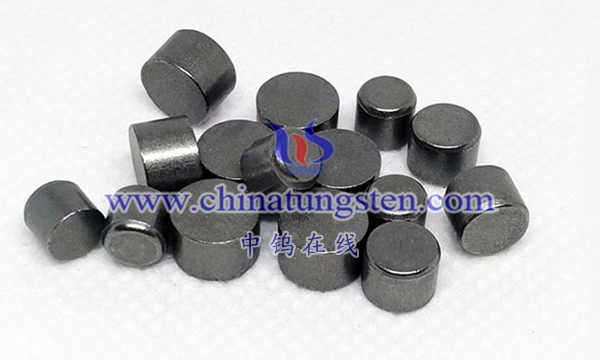

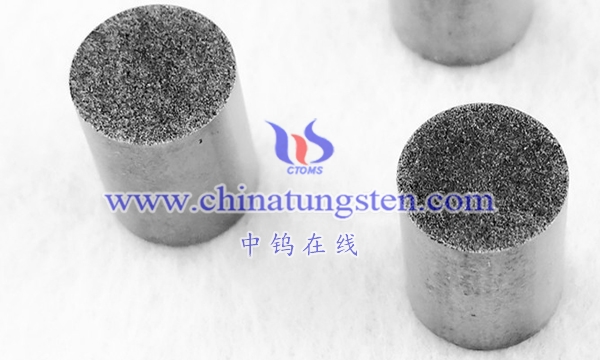

The influence of discharge plasma technology process parameters (temperature, pressure, and insulation time) on the porosity of W in barium-tungsten (Ba-W) cathodes was explored by orthogonal experiments, and the optimal process parameters required when the porosity changes within 23% to 30% were obtained. On this basis, spherical W matrices and ordinary irregular W matrices with different porosities were prepared. The study shows that the spherical porous W particles are stacked and arranged in an orderly manner, without closed pores, and the pore size distribution is concentrated and uniform. The median pore size is 1.41 μm at a porosity of 26.3%; in terms of mechanical properties, the Vickers hardness of the spherical tungsten powder matrix is lower than that of the traditional ordinary irregular tungsten porous body.

Under the conditions of pulse width of 10 μs and frequency of 1000 Hz, the cathode pulse emission current density increases first and then decreases with the increase of porosity. When the matrix porosity is 26.3%, the cathode current emission density is the largest. At 1050 ℃, the off-point emission current density can reach 24.62 A/cm2, the zero-field emission current density is 7.62 A/cm2, and the work function is 1.95 eV.

More details of tungsten barium electrode or tungsten barium cathode, please visit website: http://tungsten.com.cn/barium-tungsten-cathode.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595