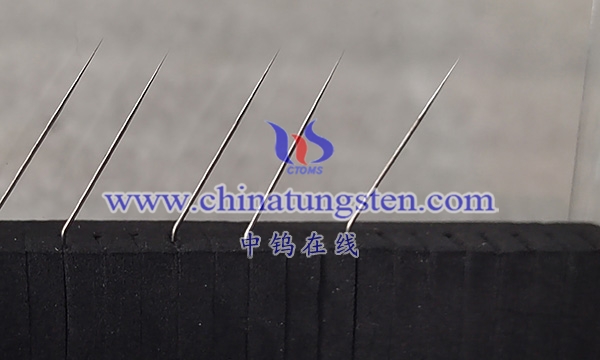

The working principle of the tungsten-rhenium contact probe is to realize the transmission and control of electrical signals through the contact between the probe needle and the circuit under test. During the test process, parameters such as the contact resistance and contact capacitance between the probe needle and the circuit under test have an important influence on the accuracy of the test results. Therefore, the tungsten-rhenium contact probe needs to have the characteristics of high precision and high stability to ensure the accuracy and reliability of the test results.

When the tungsten-rhenium contact probe contacts the circuit under test, the contact resistance and contact capacitance will change with the change of the contact area and pressure between the probe needle and the circuit under test. These changes will affect the transmission speed and stability of the electrical signal, thereby affecting the test results. Therefore, precision grinding and polishing are required during the manufacturing process of the tungsten-rhenium contact probe to ensure that the contact area and contact resistance with the circuit under test meet the test requirements.

At the same time, in order to ensure the safety and stability of the tungsten-rhenium contact probe, regular maintenance and care are required. For example, regularly check the wear of the probe needle and replace the severely worn probe needle in time; regularly clean the connecting wire and probe interface to ensure the stability and reliability of signal transmission.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595