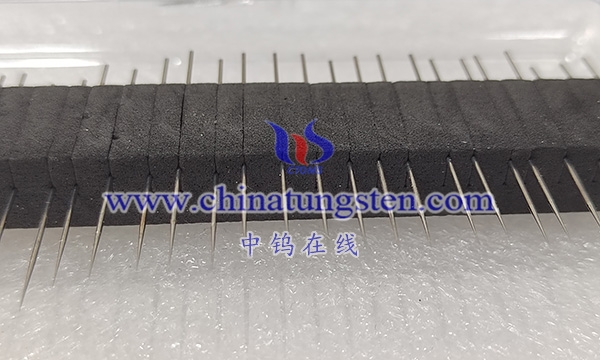

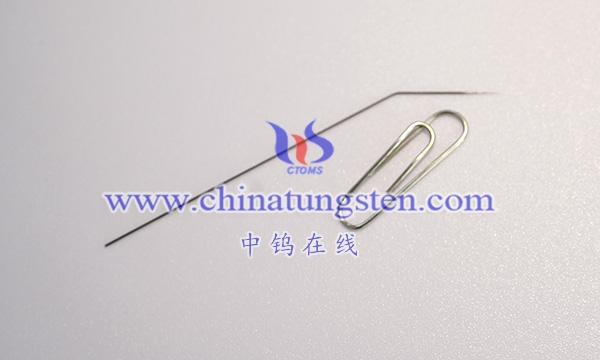

Tungsten needles are widely used in the electronics industry, mainly including the following aspects:

1. Electron beam processing

Electron beam processing is a technology that uses high-energy electron beams to perform micro-processing on materials, with the advantages of high precision, high efficiency, and high consistency. As a material with high melting point, high strength and high conductivity, tungsten needles are widely used in electron beam processing, mainly playing the following roles:

1. Focusing electron beam: Tungsten needles can be used as one of the focusing elements of the electron beam to assist the electron gun in focusing the electron beam into a finer beam spot, thereby improving processing accuracy and efficiency.

2. Support and positioning: Tungsten needles can be used as supporting and positioning elements to fix and position the workpiece for electron beam processing, ensuring the position accuracy and stability of the workpiece during processing.

3. Conducting current: Tungsten needles have high conductivity and can be used to conduct current, providing the necessary power supply and signal transmission for electron beam processing.

2. Electron microscope

Electron microscope is an instrument that uses electron beams to observe and analyze materials in detail, with the advantages of high resolution, high magnification, and high contrast. Tungsten needles play the following main roles in electron microscopes:

1. Sample manufacturing: Tungsten needles can be used as one of the sample preparation tools to assist in cutting, grinding, etching and other processing of samples to make samples suitable for electron microscope observation and analysis.

2. Fixing samples: Tungsten needles can be used to fix and support samples for electron microscope observation and analysis to ensure the stability and accuracy of samples during observation and analysis.

3. Conducting current: Tungsten needles have high conductivity and can be used to conduct current to provide the necessary power supply and signal transmission for electron microscopes.

III. Radiation detection

Radiation detection is a technology that uses radiation to perform non-destructive testing of materials, with the advantages of high precision, high sensitivity and high reliability. Tungsten needles play the following main roles in radiation detection:

1. Making radiation sources: Tungsten needles can be used as one of the radiation sources to emit X-rays or gamma rays for non-destructive testing of materials.

2. Enhancing radiation intensity: Tungsten needles can enhance radiation intensity and improve the sensitivity and resolution of radiation detection.

3. Conducting current: Tungsten needles have high conductivity and can be used to conduct current to provide the necessary power supply and signal transmission for radiation detection.

IV. Other applicationsIn addition to the above applications, tungsten needles are also widely used in other electronic industrial fields, such as electronic component manufacturing, semiconductor packaging, solar cell manufacturing, etc. In these fields, tungsten needles mainly play the role of support, positioning, and conduction to ensure the quality and performance of electronic products.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595