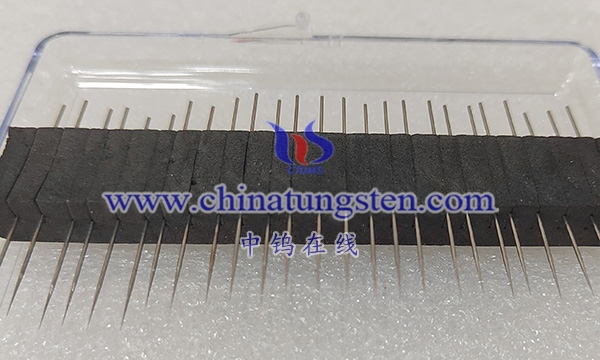

Tungsten needles have the following advantages in a vacuum environment:

1. Good thermal stability: Tungsten needles have a high melting point and excellent thermal stability, can maintain stable performance at high temperatures, and are suitable for manufacturing wear-resistant parts that need to withstand high temperatures.

2. Excellent mechanical properties: Tungsten needles have high density, high strength and good toughness, can withstand greater pressure and impact, and are suitable for manufacturing wear-resistant parts that need to withstand high-intensity wear and friction.

3. Good electrical properties: Tungsten needles have good conductivity and electrocorrosion resistance, and are suitable for manufacturing electrode materials and electronic devices that need to withstand high currents and voltages.

4. Good corrosion resistance: Tungsten needles have good corrosion resistance in most chemical media, and are suitable for manufacturing wear-resistant parts and electronic devices that need to withstand chemical corrosion.

5. Good processing performance: Tungsten needles have good processing performance, and can be manufactured into products of various shapes and sizes through forging, rolling, extrusion and other processes, which are suitable for manufacturing various wear-resistant parts and electronic devices.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595