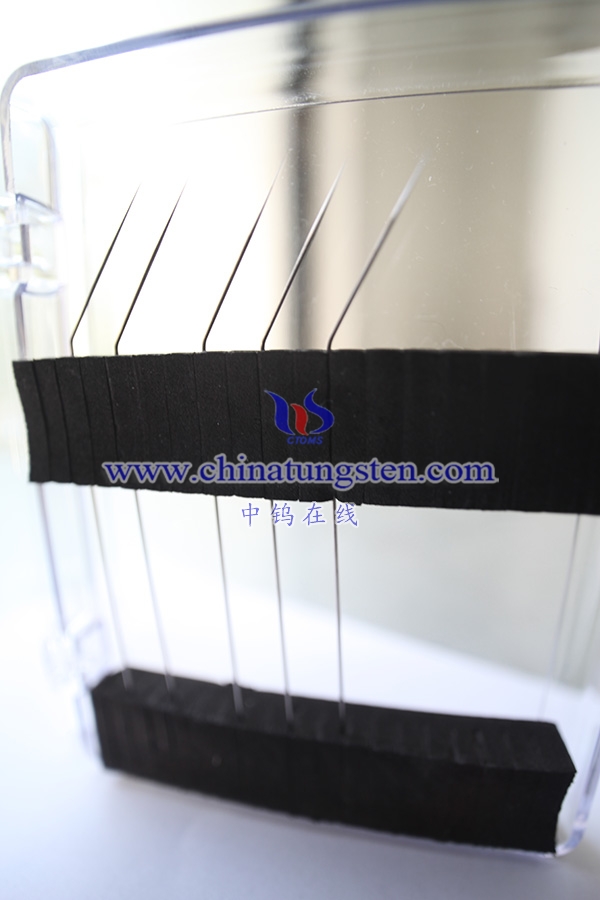

Tungsten needle acts as an ion source in ion beam etcher, and plays the following roles:

Ion beam etching is a high-precision surface processing technology that uses ion beams to accurately etch and process the surface of materials. As an ion source, tungsten needles can emit high-energy ion beams to finely etch and process samples.

Specifically, the applications of tungsten needles in ion beam etcher include:

1. Providing ion beams: As an ion source, tungsten needles can generate high-energy ion beams, which are the core of ion beam etching. The energy and direction of the ion beam determine the depth and accuracy of etching.

2. Maintaining electrical neutrality: In ion beam etching, charge accumulates on the surface of the sample, which affects the accuracy of etching. Tungsten needles can emit ion beams to help maintain the electrical neutrality of the sample surface, thereby improving the accuracy of etching.

3. Adjusting energy: Tungsten needles can control the depth and rate of etching by adjusting the energy of the ion beam. By changing the energy of the ion beam, accurate etching of different materials on the sample surface can be achieved.

4. Improve stability: Tungsten needles have high melting points and high conductivity, and can work stably under high energy conditions. This enables tungsten needles to provide continuous and stable ion beams, improving the stability and efficiency of ion beam etching.

In short, tungsten needles, as ion sources in ion beam etcher, play an important role in providing high-energy ion beams, maintaining the electrical neutrality of the sample surface, adjusting the etching depth and rate, and improving etching stability and efficiency.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595