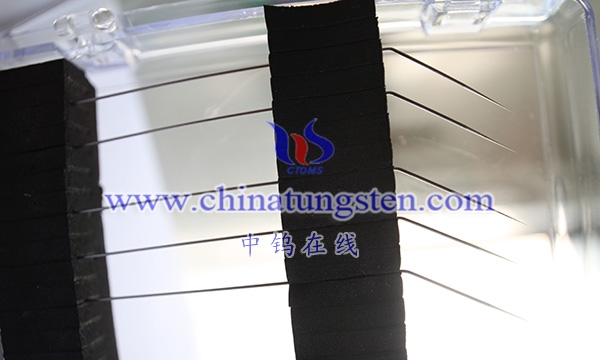

1. High melting point: The tungsten rod has an extremely high melting point, usually higher than 3400℃, which allows it to maintain its structural stability and conductivity at high temperatures.

2. High conductivity: The tungsten rod has excellent conductivity, which is conducive to the conduction of current during EDM and improves processing efficiency.

3. High resistance to electrocorrosion: The tungsten rod can resist the damage of electrocorrosion during EDM, thereby extending the service life of the electrode.

4. High processing accuracy: Due to the high melting point and conductivity of the tungsten rod, the surface roughness of the workpiece after EDM is low and the dimensional accuracy is high.

5. Wide range of applications: The discharge tungsten rod is not only suitable for the processing of light metal materials such as copper and aluminum, but also for the processing of difficult-to-process materials such as hardened steel and cemented carbide.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595