1. Improve precision and stability: With the development of science and technology and the increase in application needs, higher requirements are also put forward for the precision and stability of wafer tungsten rhenium probe cards. In the future, we will continue to explore new processes and technical means to improve the manufacturing precision and stability of wafer tungsten rhenium probe cards.

2. Research and development of new materials: With the continuous development of new material technology, more new materials will be used in the preparation and application of wafer tungsten rhenium probe cards in the future. For example, new high-temperature alloys, nanomaterials, etc. will be used in the preparation of wafer tungsten rhenium probe cards to improve their performance and service life.

3. Intelligent manufacturing: Intelligent manufacturing is an important development direction of the future manufacturing industry. By introducing artificial intelligence, the Internet of Things and other technical means, the intelligent production and processing of wafer tungsten rhenium probe cards can be realized to improve production efficiency and product quality.

4. Environmental protection and sustainable development: With the continuous improvement of environmental awareness and the need for sustainable development, the preparation and application of wafer tungsten rhenium probe cards in the future will pay more attention to environmental protection and sustainable development. For example, the use of green manufacturing technology, recycling and reuse of waste and other measures to reduce environmental pollution and resource waste.

5. Customized services: With the continuous expansion of application fields and the diversification of user needs, more attention will be paid to providing customized wafer tungsten rhenium probe card services in the future, and wafer tungsten rhenium probe card products that meet their special requirements will be tailored according to the needs of different users to meet various different application needs.

6. Rapid response and delivery: With the rapid development of the semiconductor industry, higher requirements have been placed on the rapid response and delivery capabilities of wafer tungsten-rhenium probe cards. In the future, manufacturers of wafer tungsten-rhenium probe cards need to have faster production response speeds and shorter delivery cycles to meet customer needs.

7. Predictive maintenance and remote monitoring: In the future, wafer tungsten-rhenium probe cards will become more and more intelligent, enabling predictive maintenance and remote monitoring. By real-time monitoring of the working status and health of wafer tungsten-rhenium probe cards, potential problems can be discovered in a timely manner and preventive maintenance can be performed to improve the stability and reliability of the equipment.

8. Cross-border integration and innovation: With the continuous development of science and technology, wafer tungsten-rhenium probe cards will continue to cross-border integrate and innovate with new technologies and new fields. For example, wafer tungsten-rhenium probe cards can be combined with artificial intelligence, machine learning and other technologies to realize the automation and intelligence of the testing process; or they can be applied to the biomedical field to test the performance of biochips, etc.

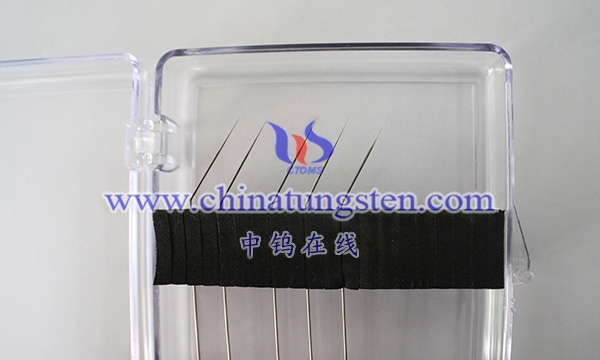

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595