The main application scenario of wafer tungsten rhenium probe cards is testing in the semiconductor manufacturing process. After the semiconductor wafer is manufactured, a series of chips will be formed on the wafer, and these chips need to be tested for performance to ensure their quality and reliability. Wafer tungsten rhenium probe cards are widely used in this process as a high-precision and high-reliability test tool.

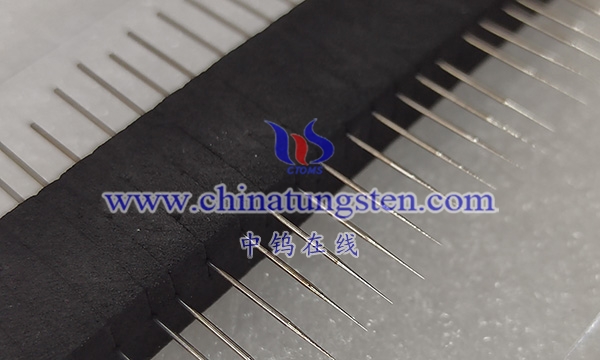

Specifically, the wafer tungsten rhenium probe card receives chip signals and screens out defective products by contacting the probe with the pads or bumps on the chip. In this process, the wafer tungsten rhenium probe card plays a key role, and its high precision and high stability ensure the accuracy and reliability of the test results.

In addition to testing in the semiconductor manufacturing process, wafer tungsten rhenium probe cards can also be used for testing other materials, such as metals, alloys, ceramics, etc. These tests usually require different probe designs and configurations to adapt to the characteristics of different materials.

Wafer tungsten rhenium probe cards are high-precision and high-reliability test tools that are widely used in testing in the semiconductor manufacturing process. The following is a detailed answer to the main application scenarios of wafer tungsten rhenium probe cards and their related data:

1. Testing in the semiconductor manufacturing process

In the semiconductor manufacturing process, the wafer is the basic unit for manufacturing chips. There are multiple chips distributed on the wafer, and each chip needs to be tested for performance to ensure its quality and reliability. Wafer tungsten rhenium probe cards play an important role in this process.

1. Testing process

In the semiconductor manufacturing process, the chips on the wafer need to go through multiple testing links to ensure their performance and quality. These testing links include: DC testing, AC testing, functional testing, reliability testing, etc. Wafer tungsten rhenium probe cards play an important role in each testing link.

2. The role of the probe card

In the testing link, the wafer tungsten rhenium probe card contacts the pads or bumps on the chip through the probe to receive the chip signal and screen out defective products. The high precision and high stability of the wafer tungsten rhenium probe card ensure the accuracy and reliability of the test results.

3. Data support for the probe card

According to data from market research companies, the global wafer tungsten rhenium probe card market size will continue to expand in the next few years. With the rapid development of the semiconductor industry, the continuous emergence of new technologies and new applications, and the trend of environmental protection and sustainable development, the market demand for wafer tungsten rhenium probe cards will continue to grow. At the same time, with the development of cross-border integration and innovation, wafer tungsten rhenium probe cards will continue to combine with new technologies and new fields to achieve wider applications and innovations.

2. Testing of other materials

In addition to testing in the semiconductor manufacturing process, wafer tungsten rhenium probe cards can also be used for testing other materials, such as metals, alloys, ceramics, etc. These tests usually require different probe designs and configurations to adapt to the characteristics of different materials.

1. Testing of metal materials

Metal materials have a wide range of applications in electronic devices, such as wires, electrodes, heat sinks, etc. Wafer tungsten rhenium probe cards can be used to test the conductivity, resistivity, hardness and other physical properties of metal materials. By using wafer tungsten rhenium probe cards for testing, the quality and performance of metal materials can be effectively evaluated to ensure their suitability for specific application scenarios.

2. Testing of alloy materials

Alloy materials are mixtures of two or more metal or non-metal elements. Alloy materials have excellent physical and chemical properties, such as high strength and corrosion resistance. Using wafer tungsten-rhenium probe cards, various properties of alloy materials can be tested, such as hardness, elastic modulus, corrosion resistance, etc. These data help evaluate the applicability of alloy materials in specific application scenarios.

3. Testing of ceramic materials

Ceramic materials have the advantages of high hardness, high wear resistance, high corrosion resistance, etc., and are widely used in electronics, aerospace, machinery and other fields. Using wafer tungsten-rhenium probe cards, various properties of ceramic materials can be tested, such as hardness, toughness, bending strength, etc. These data help evaluate the applicability and reliability of ceramic materials in specific application scenarios.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595