The following will introduce the characteristics and advantages of the tungsten-rhenium probe holder in detail from multiple aspects.

I.High precision and high stability

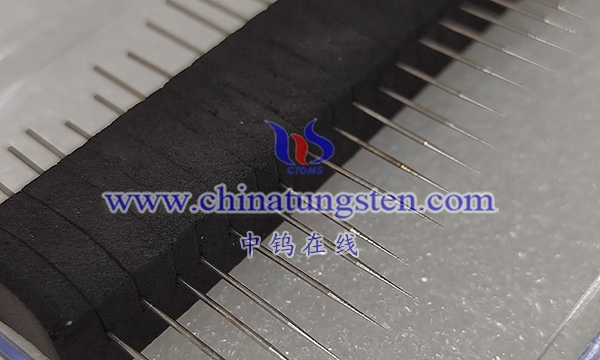

1. The tungsten-rhenium probe holder adopts a high-precision mechanical system and electronic control system, which can achieve precise probe positioning and movement, ensuring the stability and accuracy of the test.

2. The manufacturing process of the tungsten-rhenium probe holder adopts strict processing and testing processes to ensure its high precision and high stability.

3. The material selection of the tungsten-rhenium probe holder is also carefully selected, using high-strength and high-stability materials to ensure its stability and reliability for long-term use.

II. Multiple specifications and customized design

1. The tungsten-rhenium probe holder has a variety of specifications, which can adapt to tungsten-rhenium probe cards of different sizes and specifications.

2. The tungsten-rhenium probe holder can be customized according to user needs to meet the needs of different test scenarios and chip specifications.

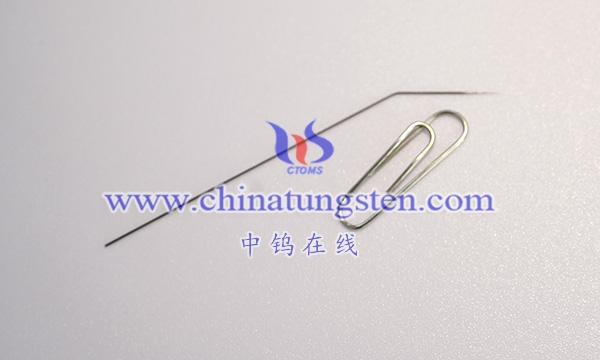

3. For the testing needs of special chips, the tungsten-rhenium probe seat can also be specially designed, such as a large-angle probe seat, a curved probe seat, etc.

III. High durability and reliability

1. The manufacturing process of the tungsten-rhenium probe seat has been optimized and improved, and high-precision processing and testing equipment has been used to ensure its high durability and reliability.

2. The material selection of the tungsten-rhenium probe seat has also been strictly screened and tested, and high-strength and high-corrosion-resistant materials are used to ensure its stability and reliability for long-term use.

3. The tungsten-rhenium probe seat also has a self-diagnosis function and a fault warning system, which can detect and solve problems in a timely manner, improving its reliability.

IV. Fast response and strong flexibility

1. The manufacturing companies of the tungsten-rhenium probe seat can quickly adjust production plans and product specifications to adapt to different testing needs and market changes.

2. The design and manufacturing process of the tungsten-rhenium probe seat has also been optimized to achieve efficient logistics and warehousing management, further improving production efficiency.

3. The control system of the tungsten-rhenium probe seat is intelligent and automated, and can quickly complete test tasks and generate test reports.

4. The tungsten-rhenium probe seat also adopts an expandable design concept, which is convenient for users to expand and upgrade functions according to different needs.

V. Data traceability and maintainability

1. The tungsten-rhenium probe seat has complete data traceability and maintainability, which allows users to easily manage and maintain data.

2. The manufacturer of the tungsten-rhenium probe seat can provide a complete product archive and data management system to help users manage and maintain data.

VI. Safety and environmental protection

1. The manufacturing process of the tungsten-rhenium probe seat meets strict safety standards to ensure the safety and environmental protection of the product.

2. The manufacturer of the tungsten-rhenium probe seat adopts environmentally friendly materials and processes to reduce the impact on the environment.

3. The tungsten-rhenium probe seat also adopts safety protection measures to ensure that it will not cause damage to operators and test equipment during the test process.

4. The manufacturing enterprises of tungsten-rhenium probe seats pay attention to safety production management and ensure the safety and health of employees through various safety systems and measures.

5. In terms of environmental protection, the manufacturing enterprises of tungsten-rhenium probe seats adopt environmentally friendly materials and processes to reduce the impact on the environment. At the same time, an environmental management system has been established and environmental protection measures have been continuously optimized to ensure the sustainable development of the enterprise.

VII. Mass production and high efficiency

1. The manufacturing enterprises of tungsten-rhenium probe seats can quickly mass-produce probe seats, thereby improving production efficiency and reducing costs.

2. By adopting automated production lines and advanced production equipment, the manufacturing enterprises of tungsten-rhenium probe seats can achieve efficient production and management.

3. By optimizing production processes and management models, the manufacturing enterprises of tungsten-rhenium probe seats can maximize production efficiency and reduce costs.

VIII. Technical support and after-sales service

1. The manufacturing enterprises of tungsten-rhenium probe seats provide comprehensive technical support and after-sales service to ensure that users can correctly use and maintain tungsten-rhenium probe seats.

2. Technical support includes technical consultation, troubleshooting, repair and maintenance, etc., to provide users with timely and effective solutions and technical support.

3. After-sales service includes product warranty, parts supply, repair and maintenance, etc., providing users with a full range of after-sales service guarantees.

IX. Application fields and application scenarios

1. Semiconductor manufacturing: In the semiconductor manufacturing process, tungsten-rhenium probe holders are widely used in chip testing, including wafer detection testing, wafer aging testing, fault diagnosis and failure analysis, process control and quality assurance. By using tungsten-rhenium probe holders, it can be ensured that the performance and quality of the chip meet the requirements and prevent bad products from entering the market.

2. Material science: In the field of material science, tungsten-rhenium probe holders are also widely used in material performance testing and research. By using tungsten-rhenium probe holders, electrical properties such as resistance, capacitance, inductance, and mechanical properties such as hardness and toughness of materials can be tested, providing important data support for material research and development.

3. Electronic components: In the field of electronic components, tungsten-rhenium probe holders also have broad application prospects. By testing electronic components, it can be ensured that their performance and quality meet the requirements and improve the reliability and stability of products.

4. Scientific research: In the field of scientific research, tungsten-rhenium probe holders also have a wide range of applications. For example, in the field of biology, tungsten-rhenium probe holders can be used to test and analyze the electrical properties of cells to provide support for disease diagnosis and treatment; in the field of physics, tungsten-rhenium probe holders can be used to test and analyze nanomaterials to provide important data support for the research and development of new materials.

5. Aerospace: In the field of aerospace, tungsten-rhenium probe holders can also be used to test and verify the electrical and mechanical properties of aerospace equipment. By using tungsten-rhenium probe holders, the reliability and safety of aerospace equipment can be ensured.

6. Automotive industry: In the field of automotive industry, tungsten-rhenium probe holders can be used to test and verify the electrical and mechanical properties of automotive parts. By using tungsten-rhenium probe holders, the quality and performance of automotive parts can be ensured to meet the requirements, and the safety and reliability of automobiles can be improved.

7. Medical devices: In the field of medical devices, tungsten-rhenium probe holders can be used to test and verify the electrical and mechanical properties of medical devices. By using tungsten-rhenium probe holders, the quality and performance of medical devices can be ensured to meet the requirements, and the safety and effectiveness of medical effects can be improved.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595