The manufacturing process of tungsten wire can be divided into the following steps:

1. Raw material preparation: The first step in tungsten wire manufacturing is to prepare the raw materials. Tungsten powder is usually used as the raw material, and tungsten bars or tungsten ingots can also be used.

2. Powder metallurgy: The tungsten powder is placed in a high-temperature furnace for powder metallurgy treatment. At high temperature, the tungsten powder is melted and extruded into filaments. This process usually requires the control of parameters such as temperature, pressure and time to ensure that the shape and size of the tungsten wire meet the requirements.

3. Heat treatment: After powder metallurgy treatment, the tungsten wire needs to be heat treated to increase its strength and hardness. Heat treatment usually includes steps such as high-temperature annealing, quenching and tempering to optimize the mechanical properties of the tungsten wire.

4. Processing and treatment: After heat treatment, the tungsten wire needs to be further processed and treated. This includes steps such as stretching, cutting, and grinding to obtain the required diameter and length. In this process, the tungsten wire may be heated and cooled many times to achieve the required shape and size.

5. Quality inspection: During the manufacturing process, the tungsten wire needs to be quality inspected to ensure that it meets the requirements. This includes steps such as appearance inspection, dimensional measurement, and mechanical property testing. Quality inspection is one of the key links to ensure the performance of tungsten wire.

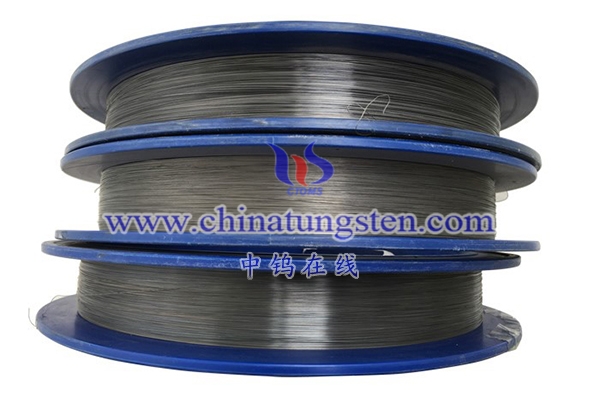

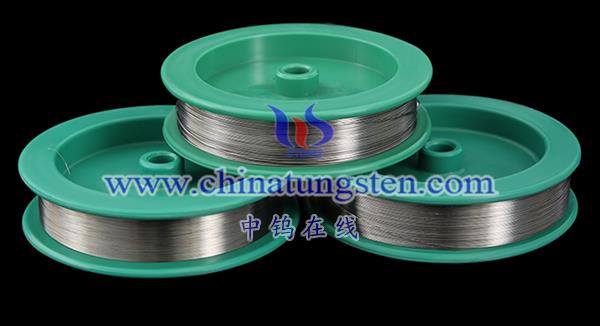

6. Packaging: After quality inspection, tungsten wire needs to be packaged to protect it from damage and contamination. The packaging usually uses moisture-proof and dust-proof materials to ensure that the tungsten wire remains in good condition during transportation and use.

In general, the manufacturing process of tungsten wire is a complex and sophisticated process that requires the control of multiple parameters to ensure that the quality and performance of the final product meet the requirements. At the same time, attention should be paid to safety and environmental protection issues during the manufacturing process to achieve sustainable development.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595