Tungsten wire is widely used in many industries. The following is the application of tungsten wire in various industries:

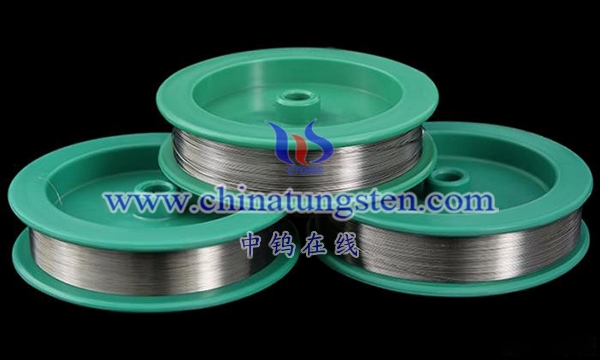

1. Light bulb manufacturing:

Tungsten wire is one of the most commonly used materials in light bulb manufacturing. It has the advantages of high melting point, high strength and high conductivity, and can withstand the test of high temperature and high voltage. In light bulb manufacturing, tungsten wire is mainly used to make filaments, which can convert electrical energy into light energy and heat energy to improve the brightness and life of the light bulb. According to statistics, the number of tungsten wires used to make light bulbs in the world reaches hundreds of thousands of tons each year.

2. Aerospace:

Tungsten alloy, as a high-performance material, is widely used in the field of aerospace. Tungsten alloy is composed of tungsten and other metals (such as nickel, iron, etc.), with the characteristics of high strength and high heat resistance, and is suitable for the manufacture of high-temperature structural components and sealing materials. In aircraft engines, tungsten alloys are widely used to manufacture high-temperature components such as turbine blades, combustion chambers and nozzles. In addition, in spacecraft, tungsten alloys are also used to manufacture high-temperature fuel storage and spacecraft structural components.

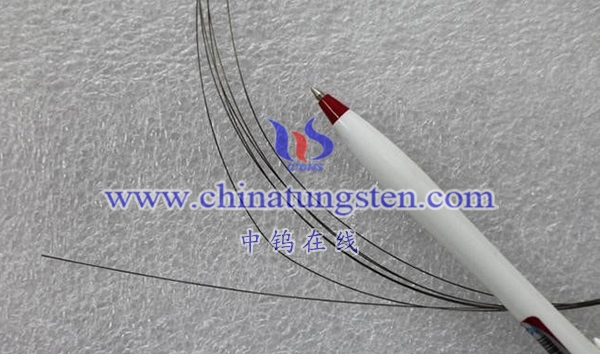

3. Electron beam processing:

In electron beam processing, tungsten wire is used as an electrode material. By using tungsten electrodes, high-energy electron beams can be guided to process materials, achieving high-precision marking, etching and welding operations. Due to the characteristics of high melting point and high conductivity of tungsten, it can maintain stable performance under high temperature and high voltage conditions.

4. Electrode manufacturing:

Tungsten wire is used as an electrode material in electrochemical processes. For example, in the process of electrolysis of salt water, tungsten wire can be used as an anode material to produce chlorine and hydrogen. Due to the characteristics of high melting point and high corrosion resistance, tungsten can maintain stable performance under high temperature and strong corrosive environment.

5. Tool manufacturing:

Due to the characteristics of high hardness, high strength and high wear resistance of tungsten wire, it is widely used in tool manufacturing. For example, tungsten steel is often used as a material in tools such as drills, milling cutters and turning tools. Tungsten steel tools have the characteristics of high hardness, high wear resistance and high impact resistance, which can significantly improve the service life and work efficiency of tools.

6. Nuclear industry:

In the nuclear industry, tungsten is widely used as an important nuclear material. In nuclear reactors, tungsten can be used as structural materials and sealing materials. Due to its high melting point and high corrosion resistance, tungsten can maintain stable performance under high temperature and strong radiation environments. In addition, tungsten wire can also be used to manufacture nuclear fuel rods and control rods.

7. Scientific research:

In the field of scientific research, tungsten as a high-performance material has also been widely used. For example, in material science research, tungsten can be used as high-temperature experimental materials and structural materials. In biological and medical research, tungsten can also be used to prepare biological samples and conduct cell experiments.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595