Testing the quality of tungsten wire is a key step to ensure that it has the required performance and durability during use. The following will introduce how to test the quality of tungsten wire from multiple aspects.

1. Appearance inspection:

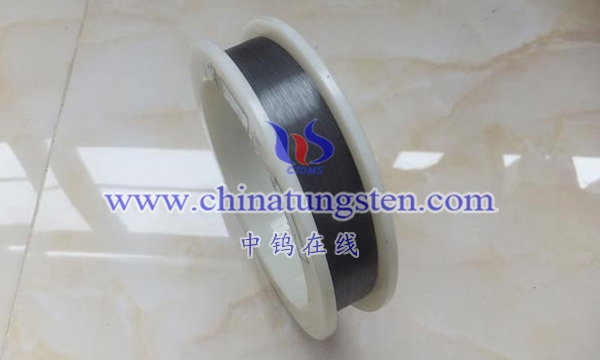

First, inspect the appearance of the tungsten wire. Observe whether the surface of the tungsten wire is smooth, free of burrs and cracks. The surface of the tungsten wire should have a uniform metallic color without obvious oxidation or contamination. If the tungsten wire has obvious surface defects, it may cause various problems in subsequent processing or use.

2. Size inspection:

Measure the diameter and length of the tungsten wire to ensure that it meets the specifications. The diameter of the tungsten wire required for different application scenarios may be different, so make sure that the diameter of the tungsten wire used meets the design requirements. At the same time, the length of the tungsten wire should also be consistent to ensure that the expected effect can be achieved during the application process.

3. Mechanical property test:

The mechanical properties of the tungsten wire are tested, including indicators such as tensile strength, yield point and elongation. These indicators can reflect the characteristics of the tungsten wire such as hardness, toughness and strength. Ensure that the tungsten wire used has sufficient mechanical properties to remain stable under load and stress.

4. High temperature resistance test:

Due to the excellent high temperature performance of tungsten wire, it is necessary to test its high temperature resistance. By testing in a high temperature environment, the changes of tungsten wire are observed, including whether oxidation, deformation or softening occurs. This helps to evaluate the stability and service life of tungsten wire in a high temperature environment.

5. Chemical composition analysis:

The chemical composition of tungsten wire is analyzed to determine its purity and composition ratio. Tungsten wire for different purposes may have different chemical composition requirements, so the appropriate tungsten wire should be selected according to the application scenario. For example, some applications may require high-purity tungsten wire, while other applications may require tungsten alloys with specific elements added.

6. Nondestructive testing:

Nondestructive testing techniques such as ultrasonic testing, radiographic testing or eddy current testing are used to detect internal defects of tungsten wire. These detection methods can detect whether there are cracks, pores or other defects inside the tungsten wire. These defects may affect the overall performance and service life of the tungsten wire, so it is necessary to ensure that the internal quality of the tungsten wire used is good.

7. Compatibility test:

For specific application scenarios, compatibility testing of tungsten wire may also be required. This includes compatibility testing with other materials or systems, as well as stability testing in specific environments. These tests can evaluate the suitability and reliability of tungsten wire in specific application scenarios.

In short, testing the quality of tungsten wire requires comprehensive consideration of multiple aspects, including appearance, size, mechanical properties, high temperature resistance, chemical composition, non-destructive testing and compatibility testing. By comprehensively evaluating these indicators, it can be ensured that the tungsten wire used has excellent performance and reliability to meet the needs of various application scenarios.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595