Production and processing flow of copper sleeve tungsten needle

1. Prepare raw materials: including copper alloy materials and high-purity tungsten powder.

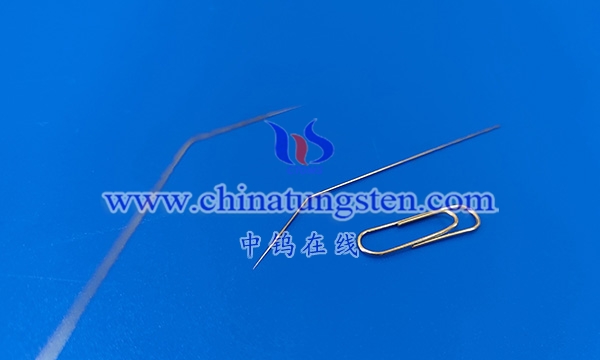

2. Pressing: Press the tungsten powder into a tungsten needle of the required shape.

3. Sintering: Sintering treatment is carried out at high temperature to give the tungsten needle a certain strength and hardness.

4. Processing: The sintered tungsten needle is finely processed, such as grinding and polishing, to meet the required size and precision requirements.

5. Assembly: Insert the processed tungsten needle into the copper sleeve to ensure that its position is accurate and stable.

6. Inspection: Perform quality inspection on the assembled copper sleeve tungsten needle, such as dimensional accuracy, surface roughness, etc., and it can be used after passing the inspection.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595