Production and processing flow of discharge tungsten pin

1. Prepare raw materials: Use high-purity tungsten powder as raw material, and make the tungsten needle body through pressing, sintering and other processes.

2. Processing: Finely process the tungsten needle body, such as grinding and polishing, to achieve the required size and precision requirements.

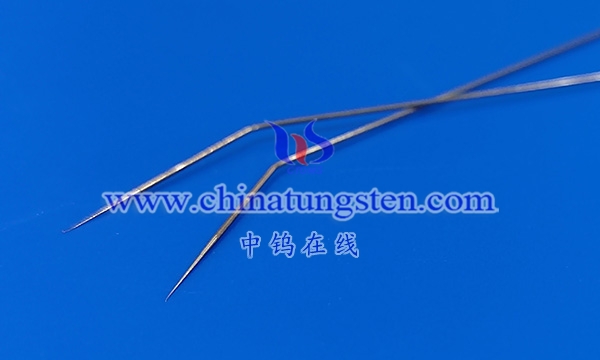

3. Assembly: Process the finer tungsten wire into a needle tip and assemble it to the tungsten needle body.

4. Inspection: Perform quality inspection on the assembled discharge tungsten pin, such as dimensional accuracy, surface roughness, etc., and it can be used after passing the inspection.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595