Tungsten wire for textiles weaving gloves has the following advantages over other metal wires:

High temperature resistance: Tungsten has a melting point of up to 3422°C, the highest of all metals, so tungsten wire can maintain its strength and shape in high temperature environments, while other metal wires may soften or melt.

High tensile strength: Tungsten wire has extremely high tensile strength and can withstand large tensile forces without breaking easily, making it suitable for braiding applications that require high-strength materials.

Abrasion resistance: Tungsten wire has high hardness and wear resistance, and can maintain good shape and structural stability under mechanical stress.

Good conductivity: Although tungsten has a slightly lower conductivity than copper or silver, its conductivity under high temperature conditions is still stable, making it suitable for use in high temperature environments.

Corrosion resistance: Tungsten has good corrosion resistance to many chemical reagents, so when used in harsh environments, tungsten wire is not easily corroded, extending its service life.

Thermal stability: Tungsten wire does not easily oxidize or volatilize at extremely high temperatures, especially in vacuum or inert gas environments, which makes it very reliable in high-temperature braiding applications.

Low Coefficient of Thermal Expansion: Tungsten has a low coefficient of thermal expansion, which means that the tungsten wire changes little in size during heating and cooling, helping to maintain the stability of the material in precision applications.

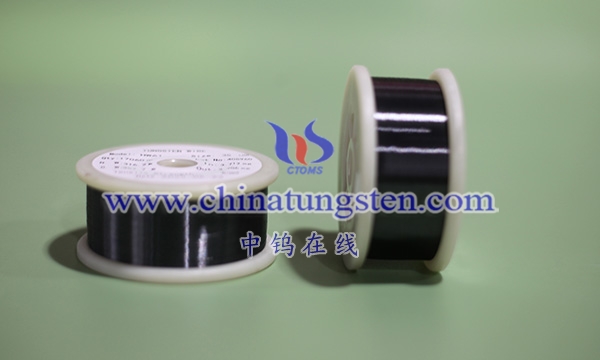

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595