A variety of professional equipment is used in the production process of tungsten wire for textiles weaving gloves to ensure the production of high-quality tungsten wire. Here is some key equipment:

Powder metallurgy equipment:

Reduction furnace: used to reduce tungstates (such as ammonium paratungstate) to prepare tungsten powder, usually using hydrogen as a reducing agent.

Mixer: used to evenly mix tungsten powder and additives to ensure the uniformity of tungsten powder.

Isostatic press: used to press tungsten powder into high-density tungsten rods, and ensure the uniformity of the rods by evenly applying pressure.

Sintering equipment:

Vacuum sintering furnace: used for high-temperature sintering of tungsten rods to improve their density and strength. The vacuum environment prevents oxidation and ensures the purity of the material.

Hydrogen sintering furnace: used for protective atmosphere during sintering to prevent oxidation of tungsten rods.

Forging and drawing equipment:

Forging machine: used for hot forging tungsten rods to improve their density and toughness.

Wire drawing machine: used to draw tungsten rods into filaments. Multiple drawing passes can gradually reduce the diameter of tungsten wires.

Annealing furnace: annealing treatment is performed on the drawn tungsten wire to eliminate the internal stress generated during the drawing process and improve the flexibility of the tungsten wire.

Surface treatment equipment:

Pickling tank: used to clean the surface of tungsten wire and remove residual lubricants or oxides.

Electrolytic polishing equipment: used to further improve the surface finish of tungsten wire and ensure its quality.

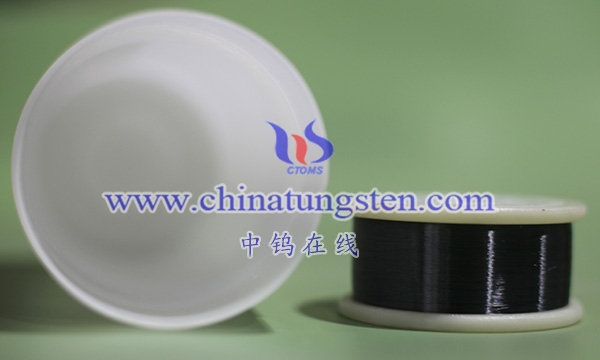

Winding and packaging equipment:

Winding machine: used to neatly wind the finished tungsten wire into coils for subsequent transportation and use.

Packaging machine: used to package tungsten wire to prevent damage or contamination during transportation.

These equipment cooperate with each other in tungsten wire production to ensure that the tungsten wire has good mechanical properties, high temperature resistance and surface quality, so that it can meet the needs of braiding applications.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595