The production process of tungsten wire for textiles weaving gloves usually includes the following main steps:

Tungsten powder preparation:

First, high-purity tungsten powder is prepared by reducing ammonium tungstate (APT) or tungsten oxide.

Mixing and pressing:

The tungsten powder is evenly mixed with a binder to form a powdery substance, and then pressed into a blank with a preliminary shape by a cold isostatic press.

Sintering:

The pressed blank is placed in a high-temperature furnace for sintering. The sintering process is carried out at a high temperature (usually over 2000°C) so that the tungsten powder particles are tightly combined to form a dense tungsten blank.

Forging and rolling:

The sintered tungsten blank is forged into a rod or wire, and its diameter is gradually reduced through multiple cold and hot rolling processes to obtain a rough tungsten wire.

Annealing:

In order to improve the ductility and strength of tungsten wire, annealing is usually performed, that is, the tungsten wire is heated in a controlled atmosphere and gradually cooled to eliminate the stress generated during processing.

Wire drawing: The tungsten wire is further drawn through a die to reduce its diameter. After multiple wire drawing, the tungsten wire of the desired diameter can be obtained.

Surface treatment: The surface of the tungsten wire may need to be cleaned, pickled or coated to improve its durability and performance during the weaving process.

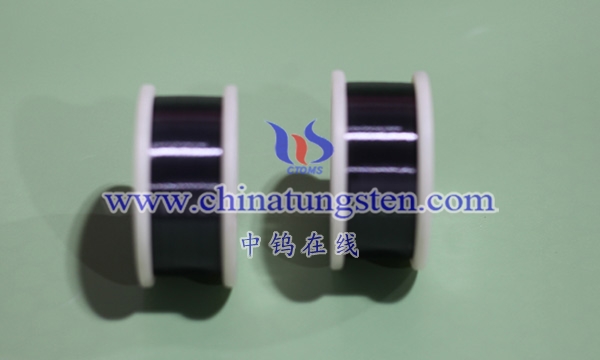

Winding and packaging:

Finally, the finished tungsten wire is wound into a coil and inspected. Products that meet the requirements will be packaged according to customer needs and ready for delivery.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595