The quality control standards for tungsten wire for textiles weaving gloves usually involve multiple aspects to ensure that its performance and reliability meet the application requirements. The following are some common quality control standards:

- Chemical composition

Purity: The main component of tungsten wire should be high-purity tungsten, and the impurity content must be controlled within a certain range to avoid affecting its performance.

Impurity content: Pay special attention to the content of elements such as oxygen, carbon, silicon, and aluminum, which may affect the mechanical properties and electrical conductivity of tungsten wire.

- Mechanical properties

Tensile strength: The tensile strength of tungsten wire must reach the standard value to ensure its strength and toughness during braiding.

Elongation: Evaluate the ductility of tungsten wire to ensure that it can withstand certain deformation without breaking during use.

Elastic modulus: Ensure that the elasticity of tungsten wire meets the requirements to maintain the stability of its shape and structure.

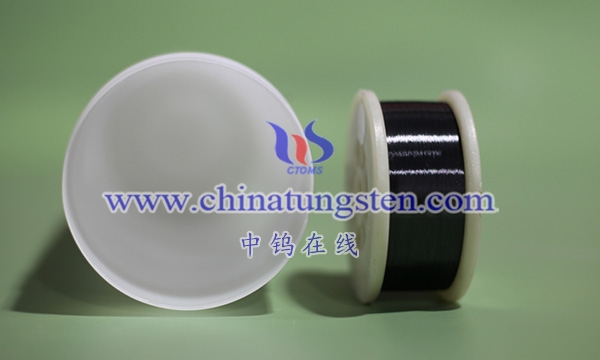

- Dimensional accuracy

Diameter tolerance: The diameter of tungsten wire should be within the specified tolerance range to ensure the consistency and density of braiding.

Length accuracy: Control the length of tungsten wire according to customer requirements, especially in mass production, the length must be consistent.

- Surface quality

Surface finish: The surface of tungsten wire should be smooth, without obvious oxidation, cracks, dents or other defects.

Surface treatment: Ensure that the surface treatment is uniform, residue-free, and meets the design requirements.

- Physical properties

Density: The density of tungsten wire should meet the standard requirements to ensure that it has the expected weight and volume characteristics.

Melting point: Maintain the high melting point characteristics of tungsten to meet the needs of high-temperature applications.

- Conductive properties

Resistivity: The resistivity of tungsten wire should be within the specified range to ensure its good conductivity, especially in electronic or electrical applications.

- High temperature resistance

Heat resistance: Under high temperature conditions, tungsten wire should maintain stability without obvious softening, melting or deformation.

- Environmental requirements

Hazardous substance control: Ensure that tungsten wire does not contain harmful substances, such as heavy metals, volatile organic compounds, etc., and comply with relevant environmental regulations and standards.

- Inspection and testing

Non-destructive testing: Use ultrasonic, X-ray and other non-destructive testing methods to check whether there are defects such as cracks and pores inside the tungsten wire.

Tensile test: Perform tensile tests to measure tensile strength and ductility to ensure that it meets the mechanical performance requirements.

Surface inspection: Use tools such as microscopes to perform surface inspections to ensure that there are no tiny defects.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595