Tungsten wire for textiles weaving gloves, market demand

The market demand for tungsten wire for textiles weaving gloves is affected by many factors. The following are some of the main demand drivers:

High temperature applications:

Aerospace: Tungsten wire is widely used in the aerospace field due to its excellent high temperature resistance, such as the manufacture of high temperature alloys and turbine engine components.

Industrial furnaces: Tungsten wire is used for heating elements in high temperature furnaces because it can maintain stable performance at extreme temperatures.

Protective clothing and safety equipment:

The high temperature and wear resistance of tungsten wire makes it an ideal material in high temperature protective clothing and safety equipment to protect workers from high temperature and thermal radiation.

Textile industry:

In industrial braiding, tungsten wire is used to make durable braiding materials due to its high strength and wear resistance, and is used in special fabrics and high-strength ropes.

Electronics and electric light sources:

Tungsten wire is used as a conductive material in electronic devices (such as light bulbs and heating elements) because of its excellent conductivity and high temperature resistance.

Radiation protection materials:

Tungsten’s high density and high melting point give it an advantage in manufacturing radiation protection materials, especially in application scenarios that require shielding high-energy radiation.

Trends in demand growth:

Emerging technologies: With the development of emerging technologies, especially in the fields of high-temperature electronics, quantum computing and new energy, the demand for tungsten wire is expected to grow.

Industrial upgrading: The upgrading of industrial equipment and the demand for higher-performance materials have driven the growth of the tungsten wire market.

Market challenges:

Cost: The high cost of tungsten wire may limit its popularity in some low-cost applications.

Alternative materials: Despite its excellent performance, tungsten wire may be replaced by other high-performance materials in some applications.

How does the global supply chain of tungsten wire for textiles weaving gloves work?

Tungsten wire for textiles weaving gloves, global supply chain

The global supply chain operation of tungsten wire for textiles weaving gloves involves multiple links, from the mining of raw materials to the manufacture and distribution of final products. The following are the main operating steps of the global supply chain:

- Raw material mining

Tungsten ore mining: The main raw materials of tungsten come from tungsten ores, such as tungsten concentrate and tungsten compounds. The main tungsten producing country is China.

Raw material processing: After mining, tungsten ore needs to be refined and processed to convert into raw materials such as tungsten concentrate, tungsten compounds (such as ammonium tungstate, sodium tungstate), etc.

- Tungsten processing

Powder production: Tungsten concentrate undergoes chemical and physical processing to produce tungsten powder. Tungsten powder is an important raw material for the production of tungsten wire.

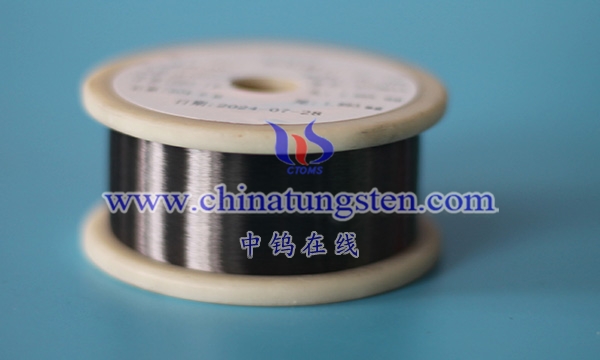

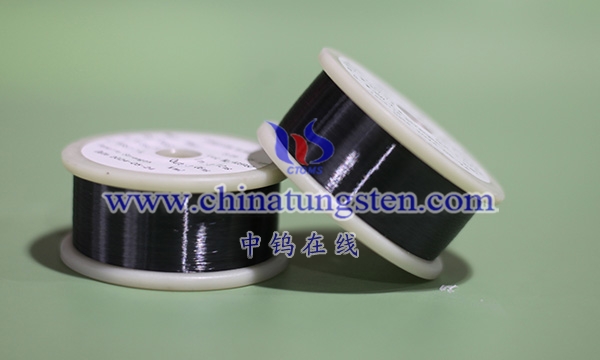

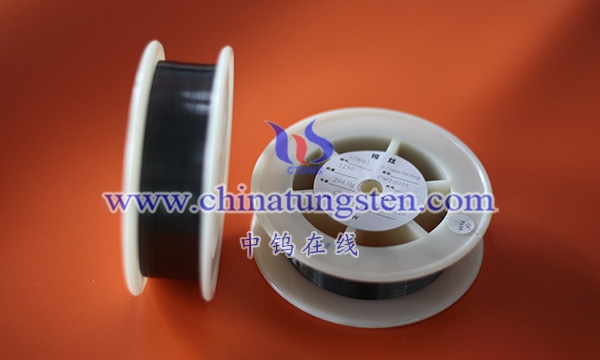

Tungsten wire manufacturing: Tungsten powder is processed into tungsten wire. This process usually includes steps such as powder pressing, sintering and wire drawing. Manufacturers who manufacture tungsten wire need to have high-precision equipment and technology.

- Product processing and weaving

Weaving processing: Tungsten wire is used to manufacture various woven products, such as high-temperature resistant textiles, protective clothing, and other industrial application products. The weaving process requires the tungsten wire to be woven into the desired shape and structure according to a specific process.

Surface treatment: Tungsten wire usually undergoes various surface treatments such as coating or painting before weaving to improve its durability and performance.

- Quality control

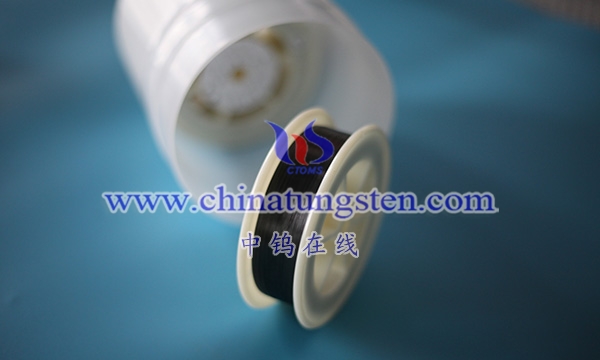

Quality testing: Throughout the production process, tungsten wire is subject to strict quality control and testing to ensure that it meets the specification requirements, especially in high-temperature and high-strength applications.

- Supply Chain Management

Inventory Management: Tungsten wire manufacturers and suppliers need to manage inventory to cope with market demand fluctuations and supply chain disruptions.

Logistics and Transportation: Tungsten wire and related products need to be transported through a global logistics network. Due to the high value and special properties of tungsten wire, special attention needs to be paid to safety and protection measures during transportation.

Market Distribution: Tungsten wire products are distributed to end users, including industrial manufacturers, textile manufacturers, and protective equipment manufacturers. Market demand and customer orders will affect the scheduling and production plans of the supply chain.

- Market Demand and Supply

Market Analysis: The supply chain of tungsten wire will be affected by changes in global market demand. For example, changes in demand in industries such as aerospace, electronics, and protective equipment will directly affect the production and supply of tungsten wire.

Price Fluctuations: Price fluctuations of tungsten raw materials will affect the production cost and market price of tungsten wire. Supply chain management needs to adapt to these fluctuations to ensure stable supply and pricing.

- Policies and Regulations

Environmental Regulations: The production and processing of tungsten wire needs to comply with environmental regulations to reduce the environmental impact during the production process.

Trade Policies: International trade policies and tariffs may affect the cross-border transportation of tungsten wire and the global supply chain.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595