The quality standards for tungsten wire for textiles weaving gloves involve many aspects, mainly including the following aspects:

- Chemical composition

Purity requirements: The purity of tungsten wire is usually required to be very high to ensure its stable performance. The purity of tungsten is generally 99.95% and above.

Impurity content: For some special applications, the impurity content in tungsten wire is strictly limited to avoid affecting its performance. For example, the control of impurity content such as chromium, nickel, and iron.

- Physical properties

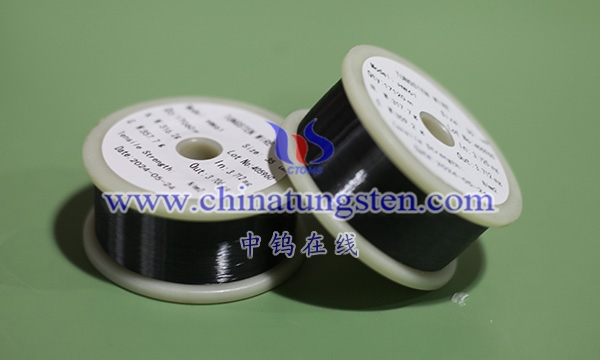

Diameter tolerance: The diameter of tungsten wire needs to meet the specified tolerance range to ensure consistency and stability.

Surface finish: The surface of the tungsten wire should be smooth without obvious defects such as cracks, scratches, etc., which is crucial for the braiding performance and the quality of the final product.

Strength and hardness: Including tensile strength and hardness tests to ensure that the tungsten wire has sufficient strength and wear resistance during use.

- High temperature resistance

Melting point: The melting point of the tungsten wire should meet the standard to ensure its stability in high temperature environments.

- Dimension and shape stability

Dimension stability: During the production process, the size of the tungsten wire should remain consistent and there should be no obvious deviation.

Shape stability: The tungsten wire should maintain a stable shape in a high temperature or high pressure environment and should not deform.

- Test method

Test standard: Use standardized test methods and equipment for testing, such as ASTM, ISO and other international standards to ensure the accuracy and consistency of the test results.

Inspection cycle: Regular quality inspection and testing to ensure that the product always meets the quality standards during production and use.

- Environmental and safety standards

Environmental protection requirements: Environmental protection requirements during the production process to ensure that the production has the least impact on the environment.

Safety regulations: Relevant safety regulations should be followed during production and use to ensure the safety of workers and users.

- Certification and quality management

Quality certification: Quality management system certification such as ISO 9001 ensures that the quality of the production process and final product meets international standards.

Production records: Maintain detailed production records and quality inspection reports for traceability and quality control.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595